37

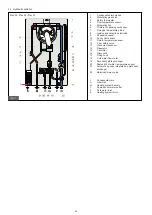

3.2.9.

Hydraulic connections

Before installation, it is recommended to clean the system in order to eliminate any impurities that could come from the components and

which could damage the circulator and the exchanger.

HEATING

The central heating flow and return must be connected to the boiler to the respective 3/4”

M

and

R

fittings (fig. 7).

When sizing the heating circuit pipes, it is necessary to take into account the pressure drops induced by the radiators, by any thermostatic

valves, by the radiator stop valves and by the configuration of the system.

It is advisable to convey the discharge of the safety valve installed in the boiler to the sewer. In the

absence of this precaution, any intervention of the safety valve can cause flooding of the room in which

the boiler is installed.

The manufacturer is absolutely not responsible for damages caused by failure to observe this technical

precaution.

SANITARY

The cold water inlet and the domestic hot water outlet must be connected to the boiler to the respective 1/2”

C

and

F

fittings (fig. 7). The

hardness of the feed water conditions the frequency of cleaning and/or replacement of the secondary plate heat exchanger.

Depending on the hardness of the supply water, the advisability of installing suitable equipment for dosing

domestic use of food-grade products that can be used for the treatment of drinking water compliant with

current regulations must be evaluated.

With feed water with hardness higher than 20°F it is always advisable to treat the water. The water coming

from common softeners may, due to the pH values that characterize it, not be compatible with some

components of the heating system.

CONDENSATE DRAIN

For the evacuation of the condensate, comply with the laws and regulations in force which are understood to be fully transcribed here.

Unless particular prohibitions exist, the condensate produced during the combustion phase must be conveyed (by means of the

condensate drain) to a drain system which makes it flow to the domestic wastewater drain network which, due to its basic nature,

contrasts the acidity of the flue gas condensate. To avoid a return of bad odors from the domestic wastewater network, it is advisable to

add an odor trap between the condensate drainage system and the domestic wastewater network. The condensate drainage system and

the domestic wastewater drainage network must be constructed with suitable materials, resistant to attack by condensation water.

The condensate drain system must be connected to the special connection (A) set up in the boiler (see fig. 15).

It is absolutely forbidden to connect the condensate drain system to the siphon inspection point (B).

The manufacturer declines all responsibility for damage caused to people, animals or things deriving from

non-observance of the above.

3.2.10.

Connection to the electricity grid

The boiler must be connected to the 230V-50Hz power supply.

When connecting, respect the polarity by correctly connecting phase and neutral.

During the installation, comply with the regulations in force, which are understood to be fully transcribed here.

An easily accessible bipolar switch must be installed upstream of the boiler, which allows you to cut off the electricity supply and carry out

all maintenance operations in safety.

The boiler power supply line must be protected by a differential magneto-thermal switch with adequate breaking capacity. The power

supply network must have a secure earth connection. It is necessary to verify this fundamental safety requirement; if in doubt, request an

accurate check of the electrical system by professionally qualified personnel.

The manufacturer is absolutely not responsible for any damage caused by failure to earth the system: the

pipes of the gas, water and heating systems are not suitable as earth connections.

B

A

fig. 15

Содержание PLAY 24

Страница 45: ...45 3 6 3 Wiring diagram fig 21...

Страница 52: ......

Страница 53: ......

Страница 55: ...2...