43

3.3. Riempimento dell’impianto

Once all the system connections have been made, the heating circuit can be filled. This operation must

be carried out with caution, respecting the following phases:

- open the radiator vent valves and make sure that the automatic valve in the boiler works;

- gradually open the filler cock (fig. 2) making sure that any automatic air vent valves installed on the system work properly;

- close the radiator vent valves as soon as water comes out;

- using the boiler pressure gauge, check that the pressure reaches a value of 1÷1.3 bar;

- close the filling cock and then vent the air again through the radiator vent valves;

- after turning on the boiler and bringing the system up to temperature, stop the pump and repeat the air venting operations;

- let the system cool down and bring the water pressure back to 1÷1.3 bar.

WARNING

The UNI CTI 8065/89 standard "Water treatment in heating systems for civil use" determines and defines the

chemical and chemical-physical characteristics that the water used in heating systems for civil use must have, in

particular: "... at in order to optimize their performance and safety, to preserve them over time, to ensure lasting

regularity of operation also to the auxiliary equipment and to minimize energy consumption, thus integrating

current laws and regulations;...".

Compliance with this rule is a legal obligation (Law 5/3/90 n.46, Presidential Decree 28/8/93 n.412).

Therefore provide for this by using specific products suitable for multimetal systems (see paragraph 3.2.4).

ATTENTION

The pressure sensor does not give electrical consent for burner start-up when the pressure is less than 0.5 bar.

The water pressure in the heating system must not be lower than 1 bar; failing that, act on the filling cock with

which the boiler is equipped (fig. 2).

The operation must be carried out with the system cold. The digital pressure gauge allows reading the pressure in

the heating circuit.

3.4. Starting the boiler

3.4.1. Preliminary checks

Before starting up the boiler, it is advisable to check that:

-

the smoke evacuation duct and the end part are installed in accordance with the instructions:

when the boiler is on, no leakage of

combustion products from any gasket is tolerated;

- l

a boiler power supply voltage is 230 V ~ 50 Hz;

-

the system is correctly filled with water (pressure gauge 1÷1.3 bar);

-

any shut-off cocks on the system pipes are open;

-

the mains gas corresponds to the boiler calibration gas: otherwise, convert the boiler to use the available gas (see section “3.7.

Adaptation to use of other gases and burner adjustment”) : this operation must be carried out by qualified technical personnel;

-

the fuel supply cock is open;

-

there are no fuel gas leaks;

-

the main electric switch upstream of the boiler is on;

-

the 3 bar safety valve is not blocked;

-

there are no water leaks;

-

the condensate drain siphon, fitted in the boiler, drains the condensate correctly and is not blocked.

3.4.2.

Turning on and off

To switch the boiler on and off, follow the "

User Instructions

"

.

Содержание PLAY 24

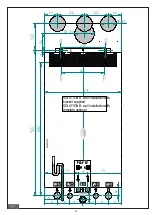

Страница 45: ...45 3 6 3 Wiring diagram fig 21...

Страница 52: ......

Страница 53: ......

Страница 55: ...2...