PROBOIL.2X user & installation guide v1e-2

22

1.3.3

Water dripping from the spout end when the handle is in the off position:

Issue description:

Possible issue & solutions:

Water is dripping (continuously from the

centre channel of the spout end aerator).

The hot water on/off valve is leaking, to confirm the fault:

1)

Turn the boiler into standby mode, press and hold the

⏻

key for 1.5 seconds to activate.

2)

Turn the 98°C tap handle off fully.

3)

If the water continues to continuously drip or leak the

boiling water valve needs to be replaced.

Water is dripping (continuously from the outer

channel of the spout end aerator).

The standard hot and or cold water on/off valve is leaking, to

confirm the fault:

1)

Isolate the hot and or cold water supplies leading to the

tap in turn, to see if the dripping stops or not.

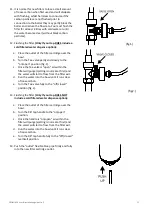

Water is dripping (intermittently from the

centre channel of the spout end aerator).

Most typically whilst the boiler is reheating

The expansion chamber in the boiler may be full:

1)

Turn the boiler target temperature to 75°

2)

Turn the 98°C tap handle on fully, run for at least 2 litres

continuously to self-empty the expansion chamber.

The incoming cold water pressure is less than 1.5 bar, at low

pressures the expansion chamber will not self empty correctly, use

a pressure gauge or use the tap specific flow test on cold water

only to confirm the incoming pressure.

Water is dripping (intermittently from the

centre or outer channel of the spout end

aerator typically shortly after each use).

This is water retained within the spout falling due to gravity and is

normal for any tap.

1.3.4

Water flow rate / stream quality:

Issue description:

Possible issue & solutions:

98°C Water flow rate is slower than expected.

Note: the typical flow rate is between

approximately between 1 and 2 litres per

minute depending on your incoming cold

water pressure and tap type, refer to the tap

specification sheet for more detail.

The boiler could be calcified:

follow the boiler descale procedure

in this manual.

Your incoming cold water pressure could be too low:

test your

incoming cold water pressure and compare it to the minimum

required pressure.

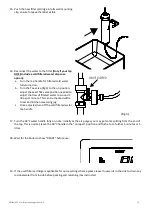

Your filter cartridge could be partly blocked with debris:

connect

the blue flexible pipe from the filter inlet directly to the boiler

(bypass the filter) to confirm, if needed replace the filter.

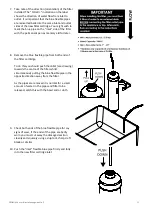

Your boiler inlet could be partly blocked with debris:

with the

water isolated remove the blue inlet wingnut

(G)

and inspect the

meshed inlet seal

(H)

underneath, clean if required.

The aerator on the tap end could be partly blocked with debris or

calcified:

follow the aerator descale procedure in this manual.

98°C water does not stop the instant the 98°C

handle is turned off.

It is normal for a short delay after the handle is turned off for

water to stop flow as the pressure remaining in the filter and boiler

tank equalise.