4.2.2 Maintenance schedule

Scheduled and non-predictable maintenance

The robot must be maintained regularly to ensure proper function. The maintenance

activities and intervals are specified in the table below.

Non-predictable situations also give rise to inspections of the robot. Any damages

must be attended to immediately!

Life of each component

The inspection intervals

do not

specify the life of each component. Values for these

are specified in the section

Expected component life on page 167

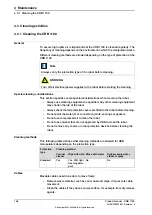

Maintenance schedule

Reference

Every

30,000

hours

ii

Every

36

months

Every

12

months

Regularly

i

Maintenance activities

x

Cleaning the robot

Check for abnormal wear or

contamination.

x

Inspecting the robot

Check for damages, defective or

lack of effectiveness.

x

Inspecting the laser scanners

Inspecting the information labels

x

Inspecting the information labels

Inspecting timing belts on page 172

x

Inspecting the timing belt

iii

Inspecting the robot cabling on

x

iv

Inspecting the robot harness

Lubricating the cable package on

x

v

Lubricating the robot harness

x

vi

Replacing the SMB battery pack

Recommended to robots with the

SafeMove option. See

Application

manual - Functional safety and

SafeMove

.

x

viii

Running the

Cyclic Brake Check

routine

vii

x

Overhaul of complete robot

i

"Regularly" implies that the activity is to be performed regularly, but the actual interval may not be

specified by the robot manufacturer. The interval depends on the operation cycle of the robot, its

working environment and movement pattern. Generally, the more contaminated environment, the

shorter intervals. The more demanding movement pattern (sharper bending cable harness), the

shorter intervals.

ii

Operating hours counted by the DTC = Duty time counter.

iii

Axis-1 and axis-4 timing belts can be accessed and inspected only after the axis-1 and axis-4

motors are removed. It is recommended to inspect the timing belts when replacing the motors.

Continues on next page

Product manual - CRB 1100

165

3HAC078007-001 Revision: J

© Copyright 2021-2023 ABB. All rights reserved.

4 Maintenance

4.2.2 Maintenance schedule

Содержание CRB 1100

Страница 1: ...ROBOTICS Product manual CRB 1100 ...

Страница 2: ...Trace back information Workspace 23B version a17 Checked in 2023 06 29 Skribenta version 5 5 019 ...

Страница 162: ...This page is intentionally left blank ...

Страница 184: ...This page is intentionally left blank ...

Страница 652: ...This page is intentionally left blank ...

Страница 698: ...This page is intentionally left blank ...

Страница 712: ...This page is intentionally left blank ...

Страница 714: ...This page is intentionally left blank ...

Страница 719: ......