ZHDN 2500-150

Installation

21

www.zepro.com

2x M12x100 8.8

80 Nm

2x M12x80 8.8

80 Nm

2x M12x80 8.8

80 Nm

2x M12x100 8.8

80 Nm

6.9

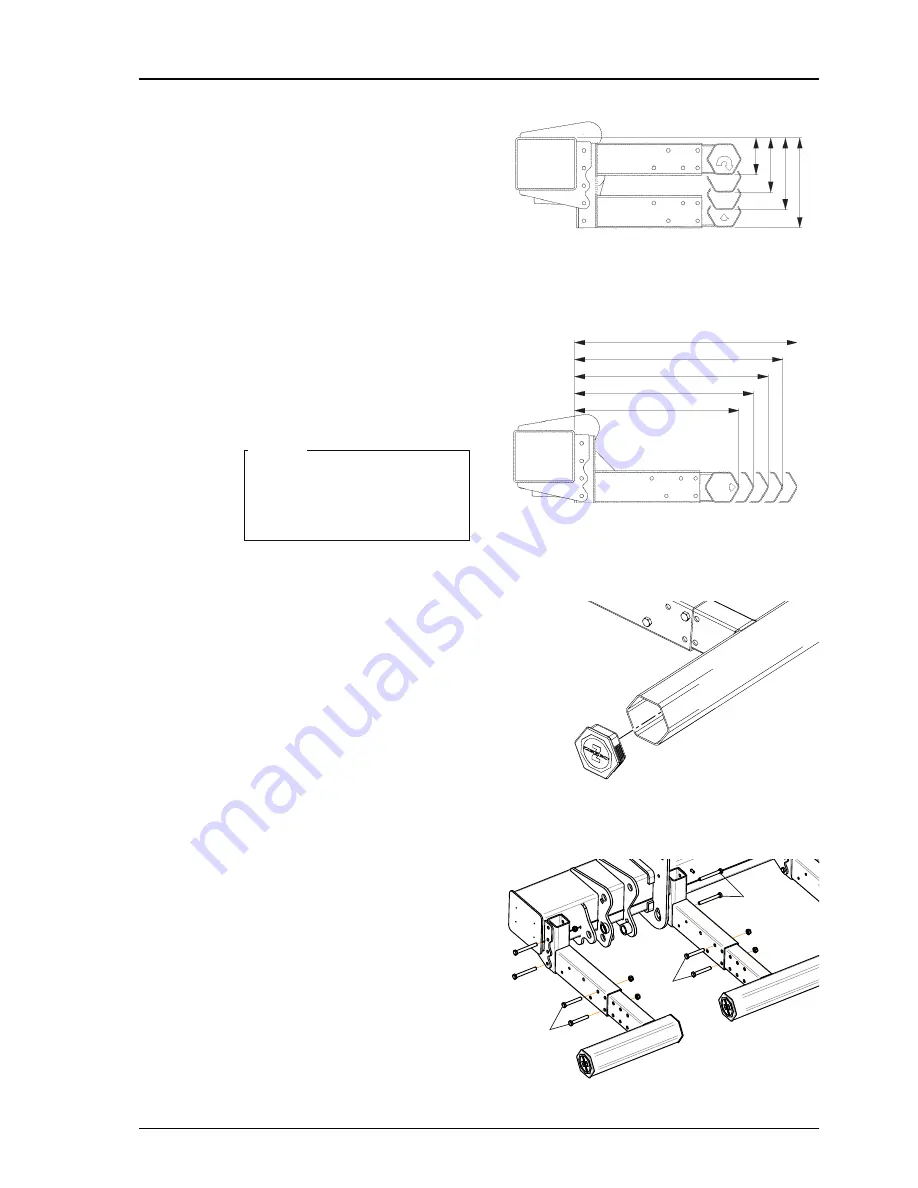

Underrun protection

Test the position of the underrun protection

without tightening the bolts to check that

the statutory dimensions are obtained.

Adjust if necessary then tighten the bolts

with a torque wrench.

1. Fit the inner brackets at one of four

heights. Select the height that meets

the statutory requirements. Use the

correct bolts M12x100. Assemble

without tightening the bolts. See

2.

Fit the outer brackets at one of five

positions. Select the position that

meets the statutory requirements.

Use the correct bolts M12x80. As-

semble without tightening the bolts.

See illustration.

The underrun protection may be

placed further back and lower

than the specified measure-

ments.

NOTE.

3. Check that the installation meets the

statutory requirements.

4. Tighten all the bolts using a torque

wrench.

Tightening torque: 80 Nm.

5. Fit the beam end caps, rotated so the

logo is the right way up, and press

them firmly to secure. If necessary,

tap carefully with a rubber hammer.

Image 22. The inner brackets can be fitted at

one of four heights

Image 23. The outer brackets can be fit-

ted in one of five positions.

Image 24. Fit the beam end caps

Image 25. Installing underrun protection

133

193

241

301

617

667

717

767

817