330

JOHNSON CONTROLS

FORM 201.21-NM3 (616)

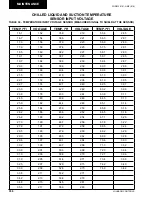

PROCEDURE

WEEKLY

QUARTERLY

SEMI-

ANNUALLY

ANNUALLY

EVERY 5

YEARS

EVERY *

HOURS

Check Oil Level

in Oil Separator

Sight Glass

X

Check Liquid Line

Sight Glass/

Moisture Indicator

X

Record System

Operating

Temperatures &

Pressures

X

Check Condensor

Coils for

dirt / debris and

clean as

necessary

X

Check Programmable

Operating Setpoints

and Safety Cutouts.

Assure they are

correct for the

application

X

Check Compressor

and Evaporator

Heater operation

X

Check for dirt in the

Panel. Check Door

Gasket sealing

integrity

X

**Check Superheat

on the Evaporator and

the Economizer feed

to the Compressor

X

**Check Condensor

Subcooling

X

**Leak check the

Chiller

X

**Sample

Compressor Oil,

check for Acid,

and replace if

necessary

X

MAINTENANCE REQUIREMENTS

FOR YCAV CHILLERS

MAINTENANCE

Summary of Contents for YCAV0267E

Page 61: ...61 JOHNSON CONTROLS FORM 201 21 NM3 616 This intentionally left blank 6 ...

Page 73: ...73 JOHNSON CONTROLS FORM 201 21 NM3 616 This page intentionally left blank 6 ...

Page 89: ...89 JOHNSON CONTROLS FORM 201 21 NM3 616 6 035 20890 009 REV LOCATION LABEL CON T LD11141 ...

Page 146: ...146 JOHNSON CONTROLS FORM 201 21 NM3 616 TECHNICAL DATA This page intentionally left blank ...

Page 147: ...147 JOHNSON CONTROLS FORM 201 21 NM3 616 6 This page intentionally left blank ...

Page 247: ...247 JOHNSON CONTROLS FORM 201 21 NM3 616 This page intentionally left blank ...

Page 269: ...269 JOHNSON CONTROLS FORM 201 21 NM3 616 This page intentionally left blank 8 ...

Page 289: ...289 JOHNSON CONTROLS FORM 201 21 NM3 616 8 This page intentionally left blank ...

Page 317: ...317 JOHNSON CONTROLS FORM 201 21 NM3 616 8 This page intentionally left blank ...

Page 348: ...348 JOHNSON CONTROLS FORM 201 21 NM3 616 MAINTENANCE NOTES ...

Page 349: ...349 JOHNSON CONTROLS FORM 201 21 NM3 616 9 NOTES ...