188

JOHNSON CONTROLS

FORM 201.21-NM3 (616)

TECHNICAL DATA

JOB NAME: _____________________________

SALES ORDER #: ________________________

LOCATION: _____________________________

SOLD BY: ______________________________

INSTALLING

CONTRACTOR: _________________________

START-UP

TECHNICIAN/

COMPANY: _____________________________

START-UP DATE: ________________________

CHILLER MODEL #: ______________________

SERIAL #: ______________________________

COMPRESSOR #1

MODEL#: ______________________________

SERIAL #: ______________________________

COMPRESSOR #2

MODEL#: ______________________________

SERIAL #: ______________________________

COMPRESSOR #3

MODEL#: ______________________________

SERIAL #: ______________________________

COMPRESSOR #4

MODEL#: ______________________________

SERIAL #: ______________________________

UNIT CHECKS (NO POWER)

The following basic checks should be made with the

customer power to the unit switched off.

Proper electrical lock out and tag pro-

cedures must be followed.

Check the system 24 hours prior to initial start:

1. Inspect the unit for shipping or installation

damage.

2. Ensure that all piping has been completed.

3. Assure the unit is properly charged and there are no

piping leaks.

4. Open each system suction service valve, discharge

service valve, economizer service valve, liquid line

stop valve, and oil line ball valve.

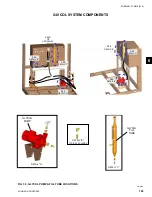

5. The oil separator oil level(s) should be maintained

so that an oil level is visible in either of the oil

separator sight glasses when a compressor is running

at high speeds for 10 to 15 minutes. An oil level

may not be visible in the sight glasses when the

compressor is off and it may be necessary to run the

compressor to obtain a level. In shutdown situations

and at some load points, much of the oil may be in

the condenser and the level in the separators may

fall below the bottom sight glass.

On systems with dual oil separators per compressor,

one separator may show a lower level or no level,

while the other separator shows a level between the

2 sight glasses. This is normal and a level is only

required in one separator. Do not add oil to raise

the level in the other oil separator.

Oil levels in single separator systems should not go

above the top of the upper sight glass. Dual separa-

tor systems should also not show oil levels above the

top of one of the sight glasses. In the rare situation

where oil levels are high, drain enough oil to lower

the level to the bottom of the top sight glass.

EQUIPMENT START-UP CHECK SHEET

Summary of Contents for YCAV0267E

Page 61: ...61 JOHNSON CONTROLS FORM 201 21 NM3 616 This intentionally left blank 6 ...

Page 73: ...73 JOHNSON CONTROLS FORM 201 21 NM3 616 This page intentionally left blank 6 ...

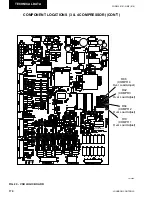

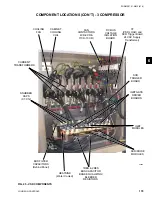

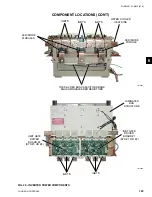

Page 89: ...89 JOHNSON CONTROLS FORM 201 21 NM3 616 6 035 20890 009 REV LOCATION LABEL CON T LD11141 ...

Page 146: ...146 JOHNSON CONTROLS FORM 201 21 NM3 616 TECHNICAL DATA This page intentionally left blank ...

Page 147: ...147 JOHNSON CONTROLS FORM 201 21 NM3 616 6 This page intentionally left blank ...

Page 247: ...247 JOHNSON CONTROLS FORM 201 21 NM3 616 This page intentionally left blank ...

Page 269: ...269 JOHNSON CONTROLS FORM 201 21 NM3 616 This page intentionally left blank 8 ...

Page 289: ...289 JOHNSON CONTROLS FORM 201 21 NM3 616 8 This page intentionally left blank ...

Page 317: ...317 JOHNSON CONTROLS FORM 201 21 NM3 616 8 This page intentionally left blank ...

Page 348: ...348 JOHNSON CONTROLS FORM 201 21 NM3 616 MAINTENANCE NOTES ...

Page 349: ...349 JOHNSON CONTROLS FORM 201 21 NM3 616 9 NOTES ...