B95W

Maintenance

06_Wartung und Pflege_en.fm - V1.0 - 1.8.17

129 / 306

6

20

17

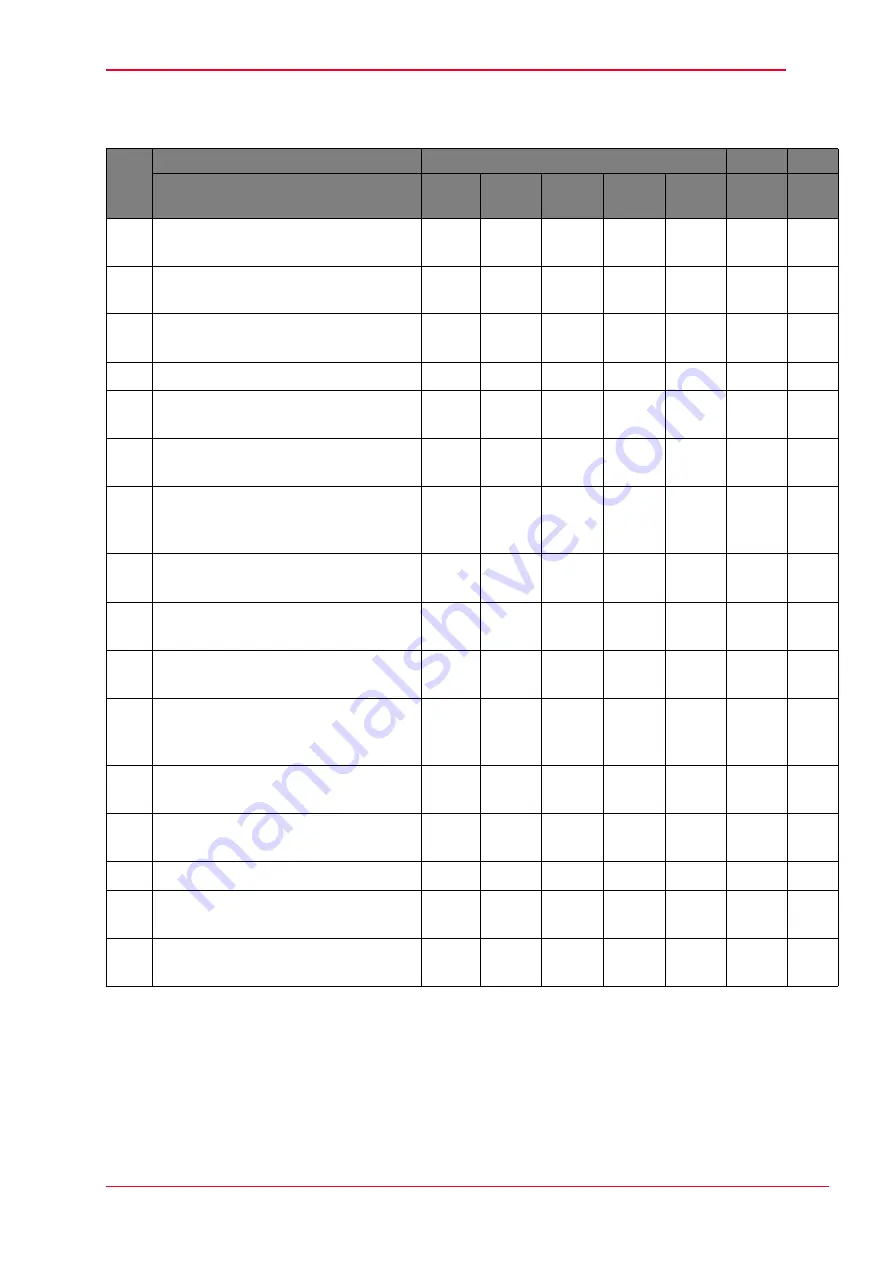

Mounting parts, hose connectors /

brackets (replace if damaged)

o

--

18

Engine speed - check upper and

lower idle speeds

o

o

19

Replace filter of the AdBlue

®

feed

pump

x

6)

20

Check pump attachment

o

o

--

21

Check acid level and battery

connections

o

o

22

Replace the dust filter for cab

ventilation

x

x

23

Check condition of tires, tire

pressure and fastening of wheel

nuts

o

o

24

Check fastening of axles and

propeller shaft

o

o

--

25

Check bushings and pins of working

equipment and replace if necessary

o

o

--

26

Check that door latches function

perfectly, and replace if necessary

o

o

--

27

Check electrical indicating and

warning elements as well as the

lighting system

o

o

--

28

Check all controls are working

properly and adjust as necessary

o

o

--

29

Check function of hydraulic axle

locking and bleed plunger cylinders

o

o

30

Check the function of the steering.

o

o

--

31

Check function and condition of

supports

o

o

--

32

Check hose-rupture safety valves

of supports

o

o

No.

Inspection

Hours in operation

Page

o = Check, maintenance

x = Replace

After

100

every

500

every

1000

every

3000

at least

2 x year

at least

1 x year

Summary of Contents for B95W

Page 2: ......

Page 8: ...B95W Table of contents 6 306 1 01_Inhaltsverzeichnis_enIVZ fm V1 0 1 8 17 10 ...

Page 52: ...B95W Description 50 306 5 05_Beschreibung_en fm V1 0 1 8 17 11 ...

Page 58: ...B95W Description 56 306 5 05_Beschreibung_en fm V1 0 1 8 17 11 ...

Page 206: ...B95W Maintenance 204 306 6 06_Wartung und Pflege_en fm V1 0 1 8 17 20 ...

Page 208: ...B95W Operation 206 306 7 07_Bedienung_en fm V1 0 1 8 17 26 ...

Page 272: ...B95W Transport 270 306 8 08_Transport_en fm V1 0 1 8 17 27 ...

Page 302: ...B95W Troubleshooting 300 306 10 10_Fehlerbeseitigung_en fm V1 0 1 8 17 30 ...

Page 309: ......