B95W

Maintenance

06_Wartung und Pflege_en.fm - V1.0 - 1.8.17

169 / 306

6

20

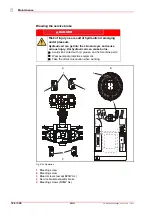

Draining the

hydraulic oil

Place the loading equipment flat on the ground.

Completely retract the bucket cylinder and the dipperstick cylinder and

completely lower the boom, articulated to the left, onto the ground.

Place the dozer blade on the ground.

Bring the hydraulic oil up to operating temperature.

All hydraulic cylinders must be retracted.

Shut down the engine.

Unscrew the ventilation filter (3).

Place suitable oil collecting vessels under the drain opening.

Attach an oil draining hose (it is in the tool bag) to the oil change valve on the

underside of the tank.

J

The oil drains away.

Flush and clean the hydraulic oil tank if necessary. To do this, remove the

return filter (1).

Drain off oil into a clean vessel.

Remove the oil drain hose and screw the protective cap on the oil change valve.

Topping up

hydraulic oil

Remove the cover from the return filter (1).

Fill up with new hydraulic oil until the right level has been reached on the sight

glass.

Fit the cover to the return filter (1).

Screw in the ventilation filter (3).

Check the filter and drain plug for leaks.

Summary of Contents for B95W

Page 2: ......

Page 8: ...B95W Table of contents 6 306 1 01_Inhaltsverzeichnis_enIVZ fm V1 0 1 8 17 10 ...

Page 52: ...B95W Description 50 306 5 05_Beschreibung_en fm V1 0 1 8 17 11 ...

Page 58: ...B95W Description 56 306 5 05_Beschreibung_en fm V1 0 1 8 17 11 ...

Page 206: ...B95W Maintenance 204 306 6 06_Wartung und Pflege_en fm V1 0 1 8 17 20 ...

Page 208: ...B95W Operation 206 306 7 07_Bedienung_en fm V1 0 1 8 17 26 ...

Page 272: ...B95W Transport 270 306 8 08_Transport_en fm V1 0 1 8 17 27 ...

Page 302: ...B95W Troubleshooting 300 306 10 10_Fehlerbeseitigung_en fm V1 0 1 8 17 30 ...

Page 309: ......