B95W

Maintenance

06_Wartung und Pflege_en.fm - V1.0 - 1.8.17

173 / 306

6

20

6.7.10 Bleeding the plunger cylinders

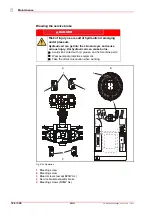

Fig. 6-29 Bleeding the plunger cylinders

1

Bleeding screws

•

Pressure supply is via the flushing oil circuit of the hydrostatic drive.

•

Latching occurs by blocking the connection line between the plunger cylinders

by means of a locking valve, which is activated by the excavator brake or the

rocker switch “pendulum axle locking”.

•

The axle may not oscillate with excavator brake engaged or toggle switch for

pendulum axle locking activated.

Bleeding

Secure the machine against rolling away

Release the parking brake.

Set the toggle switch for pendulum axle locking to “OFF”.

Allow the engine to run at medium speed.

Open the bleed screws (1) on plunger cylinder right and left one after another

until hydraulic oil emerges without bubbles.

Tighten the bleed screws.

DANGER

Risk of injury as a result of hydraulic oil under pressure

Hydraulic oil can get into the skin and eyes and cause

serious injury. Hot hydraulic oil can cause burns.

Z

Avoid skin contact with oil, grease, and hot machine parts.

Z

Wear personal protective equipment.

Z

Take the utmost precaution when working.

1

Summary of Contents for B95W

Page 2: ......

Page 8: ...B95W Table of contents 6 306 1 01_Inhaltsverzeichnis_enIVZ fm V1 0 1 8 17 10 ...

Page 52: ...B95W Description 50 306 5 05_Beschreibung_en fm V1 0 1 8 17 11 ...

Page 58: ...B95W Description 56 306 5 05_Beschreibung_en fm V1 0 1 8 17 11 ...

Page 206: ...B95W Maintenance 204 306 6 06_Wartung und Pflege_en fm V1 0 1 8 17 20 ...

Page 208: ...B95W Operation 206 306 7 07_Bedienung_en fm V1 0 1 8 17 26 ...

Page 272: ...B95W Transport 270 306 8 08_Transport_en fm V1 0 1 8 17 27 ...

Page 302: ...B95W Troubleshooting 300 306 10 10_Fehlerbeseitigung_en fm V1 0 1 8 17 30 ...

Page 309: ......