40

4. Operating procedures

Useful functions (RS485 communication function)

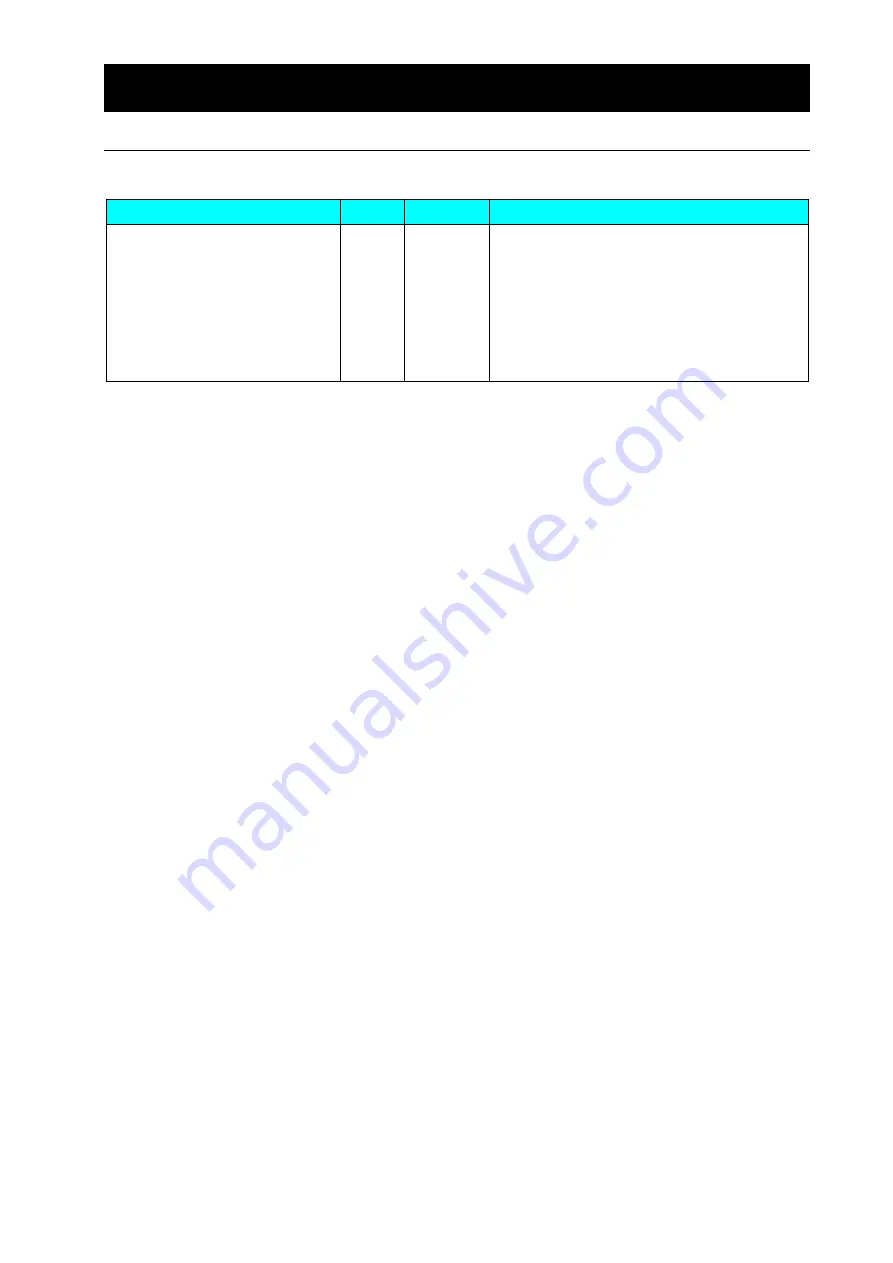

Other parameters

Name

Identifier

Command

Setting

Main measured temperature monitor

External measured temperature monitor

PV1

PV2

R/*/*/*

When input to a thermocouple

(

Ex

)

00100

:

100

℃

When input to platinum

(

Ex

(Ex

)

01000

:

100.0

℃

When input to both of a thermocouple and platinum

HHHHH

:

Measured temp. over scale

LLLLL

:

Measured temp. under scale