29

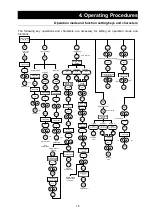

4. Operating Procedures

Creating a program

MEASURED TEMP.

℃

HEATER

ENTER

SET

TEMP.

OVER TEMP .

RUN

STOP

SUB

MENU

TIMER

FIXED

TEMP.

PROGRAM

PROTECTOR

ALARM

AUTO STOP

AUTO START

FIXED TEMP.

PROGRAM

⑨

Press ENTER key. The character t-1

that means the

set time for the first step will be displayed and the current set

time flashes.

※

Before setting a time, you need to know the temperature

increasing (or decreasing) capacity of the unit.

※

As an example, about 45 minutes are required to increase

from room temperature to 260

℃

for the model DKG610.

Thus as a rough guideline, temperature will rise by about

5

℃

for one minute. In actual setting, set a time slightly

longer including a time necessary for stabilizing.

※

Maximum settable time for the timer of each step is 999

hours 50 minutes.

⑩

When you have set a time, press

ENTER

key.

The temperature setting character Sv-2 for the second step is

displayed.

Then repeat the same steps as per the program sheet to input

temperatures and time for each step.

⑪

When you want to repeat a program pattern in the middle of a

program as in the example (program repeat), a special

procedures are necessary. In such a case, first set a time (t-7

in the example) for the step you want to perform repeat

operation (step 7 in the example) and press

SUB MENU

key

without pressing

ENTER

key. Now you can enter the Repeat

function setting mode.

※

For operation and registration (input) procedures for the

Program Repeat function, follow

“Program Repeat

operation

” on P.31.

⑫

When you have set temperature and time for the final step,

the screen will return to the initial setting screen.

Request

for

Check

operation

Be sure to perform no-load operation to check whether the set

temperature and the set time are correct before attempting actual

operation with specimens.

MEASURED TEMP.

℃

HEATER

ENTER

SET

TEMP.

OVER TEMP .

RUN

STOP

SUB

MENU

TIMER

FIXED

TEMP.

PROGRAM

PROTECTOR

ALARM

AUTO STOP

AUTO START

FIXED TEMP.

PROGRAM

5.Starting Program operation

Press

RUN/STOP

key for about one second. The Program

operation you have set will start.

The Program operation lamp comes on and the Set Temperature

indicator will show steps being operated from the step St-1

first.

※

You can press the

▼

key during operation to check the set

temperature and the remaining time for each step being operated on

the set temperature indicator.

Summary of Contents for DKG610

Page 2: ......