For Service Engineer

Service Information

SI1705004E-00=SIGMA-G5SII Service Manual

77/273

2.7.3.1.

《

Example: In the case that the nozzle does not touch the jig

》

In the case that the nozzle is lowered (in the plus (+) direction) using the HL-axis manual axis

operation, and the position where the clearance between the nozzle and jig is as close as "0" (felt

by hand) is confirmed

Select

"

DVC Check

"

and

"

MOTOR

"

in this order and select

"

Operation

"

in the

"

Motor

"

window. Then, select

"

1

"

in the

"SELECT BLOCK"

and then select

"

HL

"

.

Select "Relative" and click the value box for the "Incr (mm,deg)". The "Ten-key" window opens.

Enter "0.02" in the box and click "Set". The "Incr (mm,deg)" value will be changed to

"

0.02

"

.

Click

"

+

"

in the

"Single operation" box

and press the [START] button on the operation panel.

The HL-axis is move down by 0.02mm.

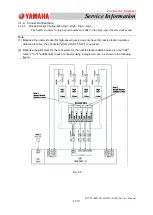

2.8. System Data Editing Procedure

(1) Refer to the following procedure for the parameter change on the Machine System

data.

In the "Sys. Setting" window (Operation Sequence: Select "Maint.", "Supervisor" and

"Sys. Setting" in this order), editing for each of various settings is available.

For some operations, the operation in the "Debug" mode is required.

Refer to "2.9 Change Procedure to Debug Mode" for the transfer procedure to the

Debug Mode.

(2) In this section, the operation procedure is described taking an example of the "Cut

operation Set-up".

When the "Block 1 Cutter" stops functioning, this function is set to "Temporarily

Disable".