-28-

Model W1805 (For Machines Mfd. Since 7/15)

O

PE

R

ATIO

NS

BACK

LEFT

RIGHT

FRONT

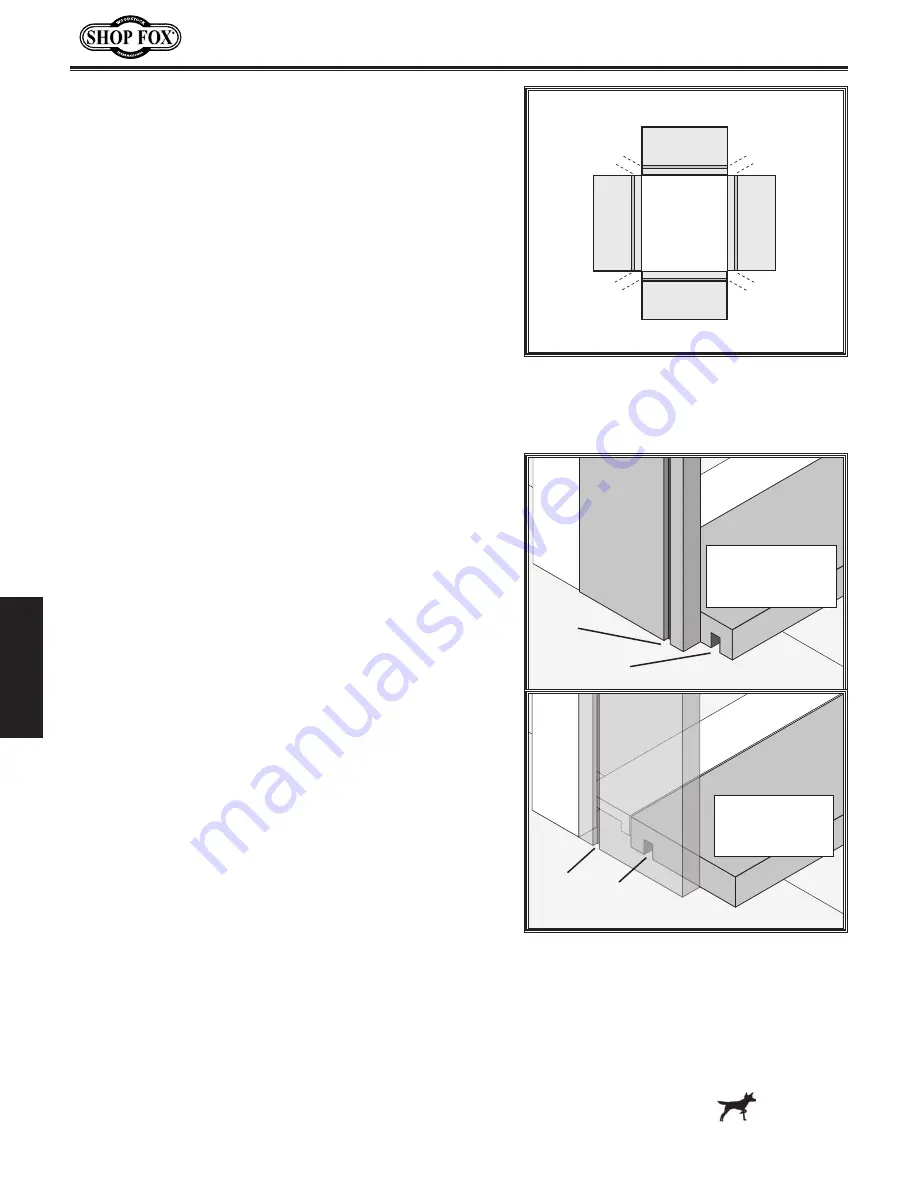

Cut 1:

Position

Dadoes Away

from Fence

Cut 3:

Position

Dadoes Away

from Fence

Cut 2:

Position

Dadoes Close

to Fence

Cut 4:

Position

Dadoes Close

to Fence

Figure.43..

Drawer pieces laid out and

marked inside face up; cutting order and

workpiece position against fences also

shown.

The standard cutting order is shown in

Figure.43

.

Figure.

44

shows the workpieces positioned with the dadoes close

to or away from the fences.

To.make.a.test.cut,.do.these.steps:

1.

Position the RIGHT workpiece on the vertical support

bar, as shown in the top illustration in

Figure.44

(with the dado positioned out and opposite the

fence), then clamp down the RIGHT workpiece.

2.

Place the BACK workpiece on the horizontal table,

as shown in the top illustration in

Figure.44

(with

the dado positioned down and opposite the fence),

then clamp down the BACK workpiece. The bottom

of both workpieces should be flush with each other

and both workpieces should be firmly against their

respective fences.

3.

Position the cutter so it is not touching the fences or

workpieces.

4.

INSTALL AND SECURE THE GUARD!

5.

Connect the machine to the power source.

6.

Make the test cut as described below, but read all of

the steps before starting, so you do not have to stop

after you begin cutting:

a.

Start the cut on the left-hand side of the vertical

piece (half of the cutter will cut into the plastic

fences), then carefully follow the template

from left-to-right, making sure the tracer pin

maintains contact with the template (otherwise

unnecessary tear-out will occur).

b.

After clearing the workpieces, do a cleanup pass

by bringing the headstock back the opposite

direction and following the template from right-

to-left.

c.

Turn the machine

OFF

, and position the cutter

clear of the workpieces and fences.

7.

Remove the workpieces from the machine and test

fit the dovetail joint.

8.

Carefully examine how the tails fit into the sockets.

The tails should fit into the sockets tightly and

both workpieces should be flush with each other.

Typically, fine-tuning the dovetail joint fit requires

balancing socket depth and the cutter adjustment,

as follows:

Horizontal

Fence

Dado

Down

Dado

Out

Vertical

Fence

RIGHT

or

LEFT

FRONT

or

BACK

Cuts 1 & 3

Dadoes Away

from Fences

FRONT

or

BACK

RIGHT

or

LEFT

Figure.44..

Workpiece positions for cuts.

Horizontal

Fence

Dado

Down

Dado

Out

Vertical

Fence

Cuts 2 & 4

Dadoes Close

to Fences

FRONT

or

BACK

RIGHT

or

LEFT

Continued on next page

Summary of Contents for Shop Fox W1805

Page 48: ......