19

Wilo-WiBooster - Installation and Operation Manual

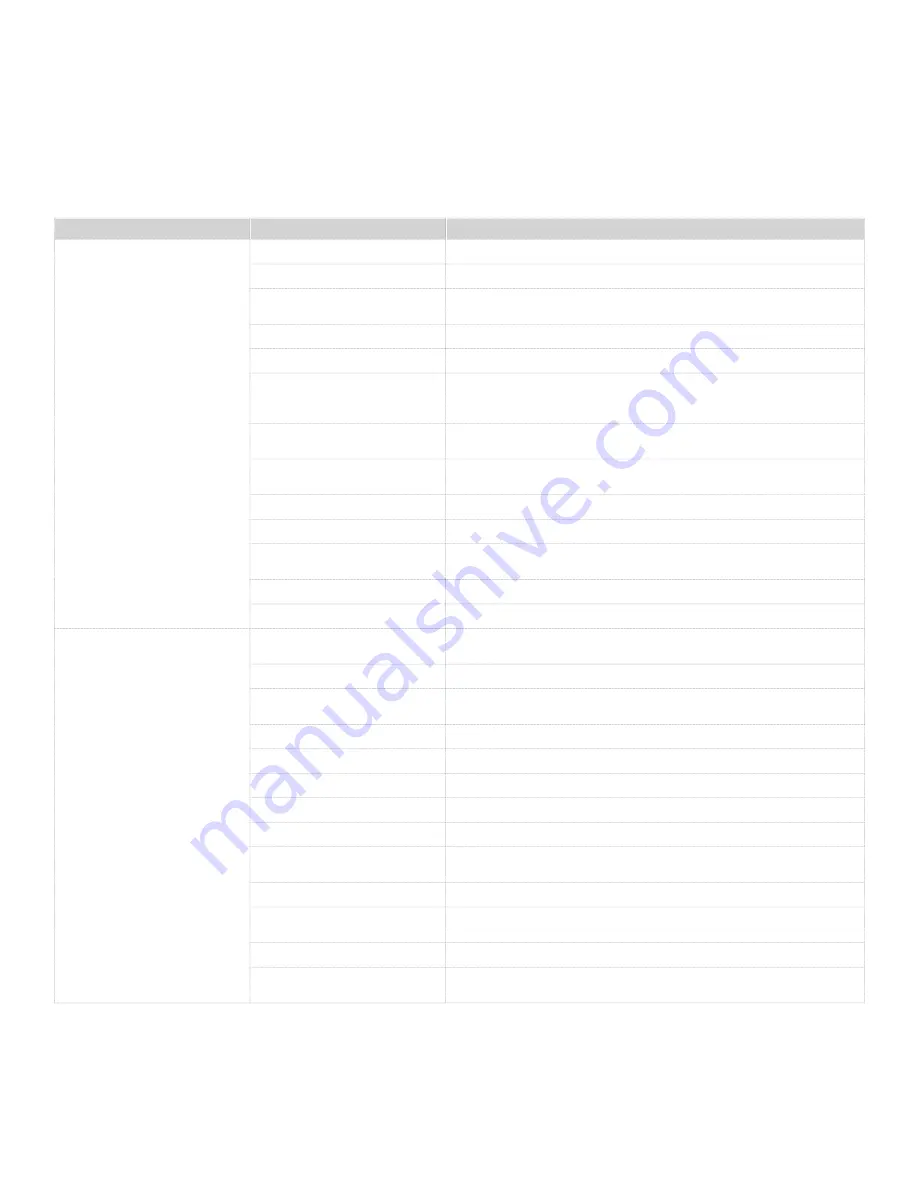

FAULT

CAUSE

REMEDIES

Pump(s) do not start

No mains voltage

Inspect fusts, cables and connections

Main switch “OFF”

Switch on main switch

Water level in break tank too low, i.e.

low-water level reached

Check break tank inlet valve/inlet pipe

Low-water level switch has triggered Check intake pressure

Low-water level switch defective

Check, if necessary replace the lowwater level switch

Electrodes incorrectly connected or

supply pressure switch incorrectly

set

Check installation or setting and correct

Intake pressure exceeds start-up

pressure

Check settings and correct if necessary

Check valve closed at pressure

sensor

Inspect, open check valve if necessary

Start-up pressure set too high

Check setting and correct if necessary

Fuse defective

Check fuses and replace if necessary

Motor protection has triggered

Check set values against the pump or motor data, measure current values and

correct setting if necessary. Check motor for defects and replace if necessary

Contactor defective

Check and replace if necessary

Turn-to-turn fault in motor

Check, if necessary replace motor or have repaired

Pump does (pumps do) not switch

off

Intake pressure fluctuates severely

Check intake pressure, if necessary take measures to stabilise supply pressure

(e.g. pressure reducer)

Intake pipe blocked or shut off

Check inlet pipe, if necessary remove blockage or open check valve

Nominal diameter of inlet pipe too

small

Check the inlet pipe, increase the crosssection for the inlet pipe if necessary

Inlet pipe incorrectly installed

Check inlet pipe, if necessary change pipe guide

Air in inlet

Check, if necessary seal pipe. Vent pumps

Impellers blocked

Check pump, if necessary replace or have repaired

Non-return valve leaking

Check, if necessary replace seal or replace non-return valve

Non-return valve blocked

Check, if necessary remove blockage or replace non-return valve

Gate valve in system closed or not

sufficiently open

Check, open the check valve completely if necessary

Volume flow too large

Check pump data and default values and correct if necessary

Check valve closed at pressure

sensor

Inspect, open check valve if necessary

Switch-off pressure set too high

Check setting and correct if necessary

Direction of motor rotation false

Check the direction of rotation and correct by changing over the phases if

necessary

continued next page

7.3

WiBooster PLC levels of access

The PLC includes three levels of control access: monitoring,

operator settings and advanced settings. These levels of access

prevent unauthorized individuals from accessing parameters

that are critical to proper function of the Wilo WiBooster. If

the “Operator Settings” or “Advanced Settings” buttons are

pressed from the main screen a keyboard will appear to allow a

password to be entered for the requested level of access.

7.3.1

Troubleshooting Guide