Page 30

Installer’s Information Manual

•

Furnace-room or closet combustion and ventilation air

openings must be clear and free.

•

Furnace combustion air openings must be clear and

free.

•

Return air duct must be physically sound, sealed to the

furnace casing and ending outside the space

containing the furnace.

•

Supply air ducts and return air ducts must be clear and

free, and without air leaks.

•

Registers and return grilles must be open and

unobstructed by rug, carpet or furniture.

•

The furnace must be well supported without sagging,

cracks, gaps, etc. around the base.

•

There must be no obvious signs of deterioration of the

furnace. Inspection must include burners, heat

exchanger, inducer pan and draft inducer.

•

Inspect all electrical wiring and connections, including

electrical ground.

•

Gas pipes must be checked for leaks using a

commercial soap solution made to detect leaks.

•

Main burners must be in good adjustment as shown in

the User’s Information Manual. Main burner flame

must be clear blue and centered within the heat

exchanger openings.

•

Flame holders, located inside each main burner,

should be checked for lint and debris.

•

Check the furnace area for combustible materials,

flammable liquid near the furnace, corrosive materials,

insulation material within 12 inches of the furnace and

signs of high water levels.

•

Inspect, clean, or repair as needed the following items:

blower housing, blower motor, blower wheel, air filters,

draft inducer and cooling coil.

NOTE: Blower motor and inducer motor do not require

oiling.

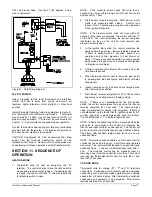

SECTION 27. BLOWER ASSEMBLY

REMOVAL

Follow these steps to remove blower assembly:

1. Turn off furnace electrical power.

2. On downflow furnaces, remove vent pipe inside

furnace.

3. Disconnect room thermostat wires from 24-volt terminal

strip on Control.

4. Locate the five blower motor wires that feed though the

casing hem.

5. Label blower motor wires for proper replacement.

6. Disconnect blower motor wires from Control. See

Figure 30.

7. Remove 2 screws holding blower door in place.

Remove blower door.

8. Pull blower motor wires through casing hem.

9. Remove

power-disconnect

assembly located in the

middle of the blower deck.

10. Remove 2 screws holding blower assembly to blower

deck.

11. Slide blower assembly out.

12. After cleaning blower assembly, re-assemble in

reverse order making sure speed selections are in

original positions.

SECTION 28. ACCESSORIES

THERMOSTATS: These are quality thermostats. Choose

from the T87 (round w/subbase), T834 (heating and

cooling) or the T8699 (Chronotherm III), available in white

only.

NATURAL GAS TO PROPANE CONVERSION KIT

(BELOW 6,000 ft): Includes propane regulator spring kit

and main-burner orifices.

PROPANE TO NATURAL GAS CONVERSION KIT

(BELOW 6,000 ft): Includes natural gas regulator spring kit

and main-burner orifices.

U.S. HIGH-ALTITUDE NATURAL GAS TO PROPANE

CONVERSION KIT (ABOVE 6,000 ft): Includes propane

regulator spring kit, main-burner orifices, and high-altitude

pressure switch.

U.S. HIGH-ALTITUDE PROPANE TO NATURAL GAS

CONVERSION KIT (ABOVE 6,000 ft): Includes natural gas

regulator spring kit, main-burner orifices, and high-altitude

pressure switch.

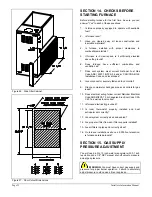

BOTTOM FILTER CABINET: Four sizes - one size for each

furnace casing size. Includes one high velocity, washable

filter.

SIDE FILTER CABINET: Attaches to either side of the

furnace. One size fits all. Includes one 16" x 25" x 1" high

velocity, washable filter.

BOTTOM CLOSURE: Seals bottom of furnace when only

side return is used. DOWNFLOW FILTER KIT: Filter

support mounts between furnace and downflow return

plenum. Requires an access panel in plenum. Includes

two 16" x 20" x 1" high velocity, washable filters.

FILTERS: High velocity, washable filters, available in

cartons of 10. Sizes include 14 x 25 x 1, 16 x 25 x 1, 20 x

25 x 1, and 16 x 20 x 1 inches.

COMBUSTIBLE FLOOR BASE: Allows downflow

installation on wood flooring. One size fits all.