Page 16

Installer’s Information Manual

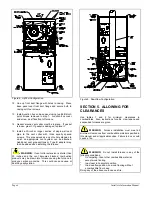

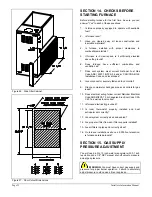

Figure 20. Changing position of elbow for gas line entry.

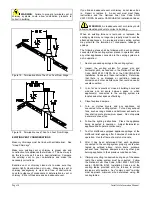

INSTALLATION

1. Install gas pipe to inlet side of furnace gas control. If

no inlet elbow is used, use a backup wrench on the

square ends of the gas control. If the inlet elbow is

used, place backup wrench on the square ends of the

inlet elbow rather than on gas control.

WARNING

: Do not thread gas pipe too far. Doing

so may cause a gas leak or malfunction of furnace gas

control resulting in a fire or explosion.

2. When using black iron gas pipe, install a ground joint

union immediately upstream of the furnace to allow for

easy servicing of burner assembly and furnace gas

control. Ground joint union must be listed by a

nationally recognized testing laboratory.

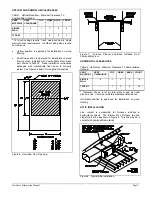

3. After ground joint union install a drip leg (sediment

trap). A convenient way to make a drip leg is by using

a 1/2" NPT to 1" NPT tee. Then install a 1-1/2 inch

long, 1" NPT nipple in tee with a 1" NPT pipe cap to

complete drip leg.

4. Install an equipment shut-off valve in the gas supply

line immediately upstream of the drip leg tee.

Equipment shut-off valve must be listed by a nationally

recognized testing laboratory.

5. Install a 1/8-inch NPT plugged tapping in the gas

supply line immediately upstream of the equipment

shut-off valve. The 1/8-inch NPT plugged tapping must

be accessible for test gauge connection.

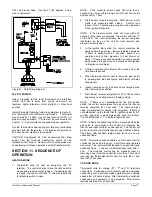

TESTING FOR LEAKS

Isolate furnace and its gas control from gas supply line

during leak checks. Gas supply line test pressure

determines how you isolate gas control.

The furnace and its gas control must be disconnected from

the gas supply piping system at the ground joint union

during any pressure testing of the system at test pressures

greater than 1/2 psi (14 inches W.C.).

The furnace must be isolated from the gas supply piping

system by turning off the equipment shut-off valve during

any pressure testing of the system at test pressures equal

to or less than 1/2 psi (14 inches W.C.).

WARNING

: When test pressure is above 1/2 psi

(14 inches W.C.), completely disconnect furnace and gas

control from gas supply line. Failure to isolate furnace and

gas control from test pressure could damage them, causing

gas to leak, resulting in fire or explosion.

Use a commercial soap solution made to detect leaks and

check all gas piping connections. Bubbles indicate gas

leakage. Seal all leaks before proceeding.

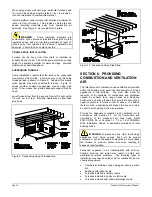

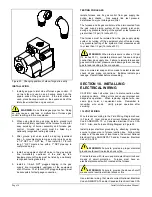

SECTION 10. INSTALLING

ELECTRICAL WIRING

CAUTION: Label all wires prior to disconnection when

servicing controls. Wiring errors can cause improper and

dangerous operation. When replacing original wire, use

same type, color, or equivalent wire. Remember to

renumber wire ends. Verify proper operation after

servicing.

115 VOLT WIRING

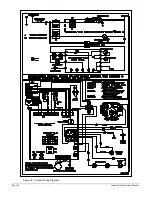

Wire furnace according to the Field Wiring Diagram shown

in Figure 21, local codes and current National Electrical

Code ANSI/NFPA 70 or Canadian Electrical Code CSA

C22.1. Also, see Furnace Wiring Diagram in Figure 22.

Install proper electrical grounding by attaching grounding

source to green wire in furnace junction box. Follow local

codes or in the absence of local codes, the current National

Electrical Code ANSI/NFPA 70 and/or Canadian Electrical

Code CSA C22.1.

WARNING

: Failure to provide a proper electrical

ground could result in electric shock or fire.

Provide furnace with its own separate electrical circuit and

means of circuit protection. Furnace must have an

electrical disconnect switch located at the furnace.

WARNING

: Failure to provide the above shut-off

means could result in electrical shock or fire.

Use electrical wiring that meets current National Electrical

Code ANSI/NFPA 70 and/or Canadian Electrical Code CSA