Installer’s Information Manual

Page 11

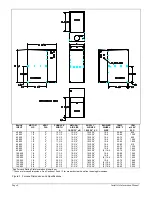

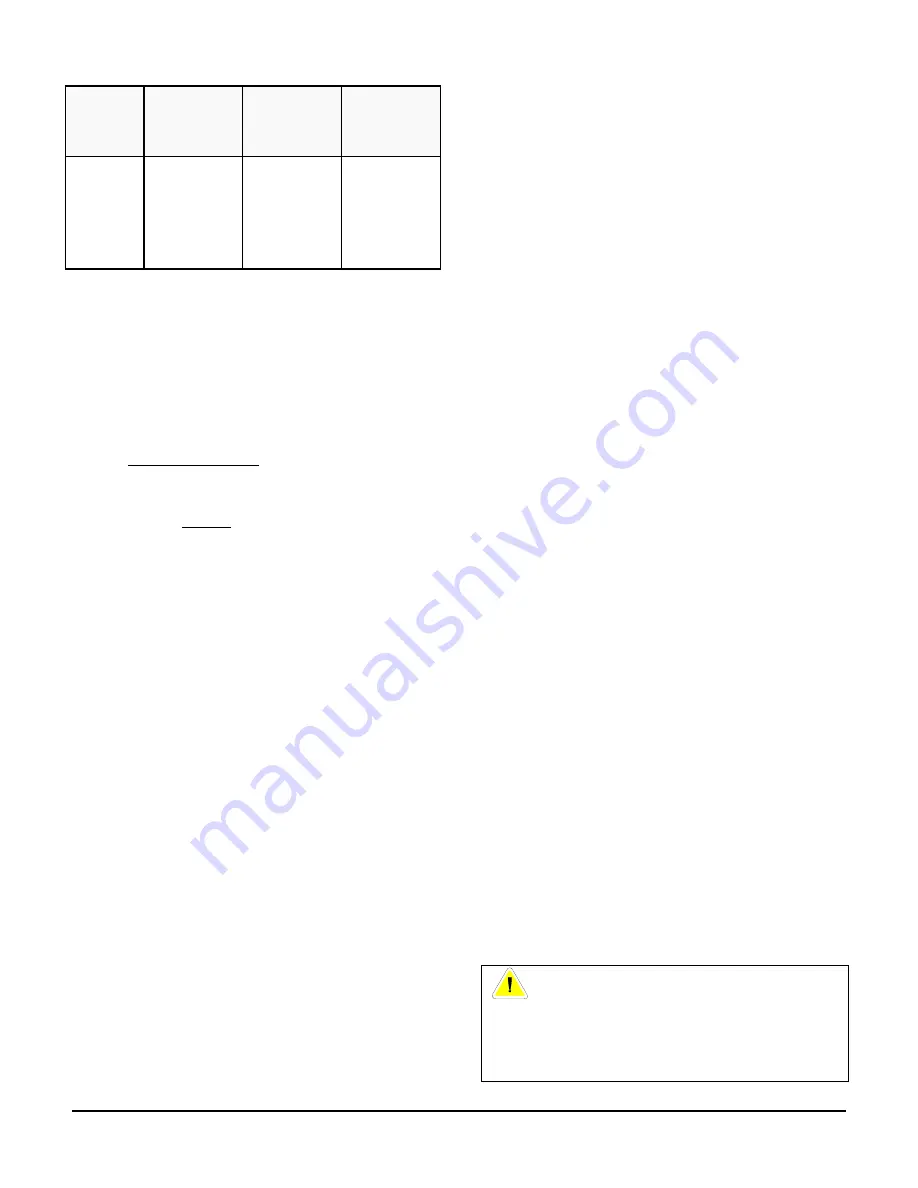

Table 4. Free Opening Area Based On One Square Inch

Per 2000 Btu/hr.

Total input

Btu/hr

Required Free

Area Per

Opening

(square

inches)

Minimum

Round Pipe

(inches dia.)

Maximum

Btu/hr Input

For Given

Pipe Diameter

40,000 20

6

56,000

60,000 30

7

76,000

80,000 40

8 100,000

100,000 50

8

100,000

120,000 60

9

127,000

140,000 70

10 157,000

160,000 80

11 190,000

180,000 90

11 190,000

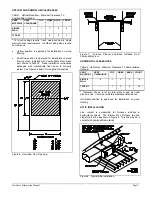

Example: Furnace is 100,000 Btu per hour input and is to

be installed in a confined space that contains no other gas

appliances. Rectangular combustion and ventilation air

ducts will run horizontally from outdoors to furnace space.

Calculate the free area required.

Because combustion and ventilation air ducts run

horizontally, allow 2,000 Btu per hour.

Furnace input (Btu/hr)

= Free area required

2,000 Btu/hr

per square inch

100,000

= 50 square inches

2,000

Both of the ducts must have a minimum cross sectional

area of 50 square inches.

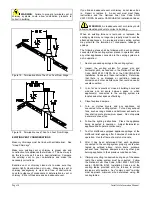

LOUVERS, GRILLES AND SCREENS

If you are installing a louver, grille or screen over

combustion and ventilation air openings, the free area of

the louver or grille must be at least as big as the free area

determined above. Louver, grille and screen manufacturers

supply technical data that usually includes the "free area." If

you do not know the free area, assume that wood louvers

have 20 to 25% free area. Assume metal louvers and

grilles have 60 to 75% free area.

You must fix combustion and ventilation air louvers and

grilles in the open position or interlock them with furnace

operation so that they open automatically. Do not use

screen smaller than 1/4-inch mesh.

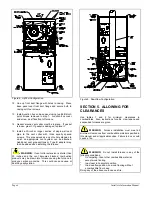

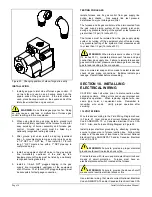

SECTION 7. PROVIDING PROPER

VENTING

This furnace must be connected to a venting system

adequate to remove flue and vent gases to the outside

atmosphere. It must be vented in accordance with Part 7,

Venting of Equipment, of the National Fuel Gas Code ANSI

Z223.1, or Section 7, Venting Systems and Air Supply for

Appliances, of the CAN/CGA B149 Installation Codes. It

must also be vented in accordance with local building codes

and vent manufacturer's instructions.

The furnaces covered by this manual are design-certified as

Category I appliances. Category I appliances must operate

at negative vent static pressure with a vent gas temperature

high enough to avoid condensation in the vent. Category I

appliances rely on the buoyancy of combustion products to

vent and must be vented vertically or nearly vertically,

unless equipped with an approved mechanical venter.

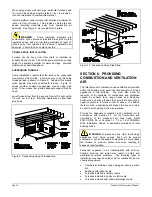

In most cases, proper venting is achieved by using a

conventional vertical vent or chimney. However, it is not

uncommon to have an installation where venting through a

sidewall becomes necessary. For information on venting

through a sidewall using a mechanical (power) venter, see

Section 8, “Sidewall Venting”. This furnace must not be

vented with plastic pipe.

To supplement national and local codes, instructions for

venting as Category I are contained in this manual and in

an addendum, “Venting Tables For Category I Venting”.

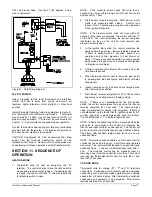

DEFINITIONS

"Vent" and "Chimney" refer to open passageways that

convey vent gases from the furnace, or its vent connector,

to the outside. Vents and chimneys usually run vertically or

nearly vertical. When they serve only one gas appliance,

they are called "dedicated" vents or chimneys. When they

serve multiple gas appliances, they are called "common"

vents or chimneys.

"Vent Connector" refers to a pipe or duct that connects the

furnace to a vent or chimney. Vent connectors usually run

directly from the furnace's vent collar to the vent or

chimney. Vent connectors may have vertical and horizontal

runs.

"Venting System" refers to a continuous open passageway

from the vent collar to the outside. Venting systems usually

have a vent connector(s) and a vent or chimney. Venting

systems commonly serve a single furnace or a single

furnace and a water heater. Other multiple-appliance

venting systems are less common.

"Fan-Assisted Combustion System" refers to an appliance

equipped with an integral mechanical means to either draw

or force products of combustion through the combustion

chamber and/or heat exchanger. This furnace uses a draft

inducer to draw combustion products through the heat

exchanger and is considered to have a fan-assisted

combustion system. Category I furnaces with fan-assisted

combustion systems must not be vented into single wall

metal vents.

GENERAL DESIGN CONSIDERATIONS

These instructions are for venting this furnace as a

Category I appliance. Venting system components

discussed in these instructions are not appropriate for

Category III or IV appliances that have positive pressure

venting systems.

WARNING

: Do not connect this furnace to a vent

system used by other Category III or IV appliances. Do not

connect it to vents with mechanical draft systems operating

at positive pressure. Improper venting could allow

combustion products to collect in building during use,

resulting in fire, nausea or death by asphyxiation.