Installer’s Information Manual

Page 19

CONTINUOUS FAN OPERATION

When the thermostat calls for continuous fan (G) without a

call for heat or cool, the indoor fan is energized on the

heating speed after a 0.25 second delay.

Note: This brief on delay is to allow the “G” terminal to

energize slightly before “Y” and an external change-over

relay to switch from “G” to “W” without causing momentary

glitches in the blower output. The fan remains energized as

long as the call for fan remains without a call for heat or

cooling.

If a call for cooling (Y) occurs during continuous fan, the

blower will switch over to cool speed. If a call for heat (W)

occurs during continuous fan, the blower will de-energize.

NOTE: A call for continuous fan is ignored if the control is

in lock-out.

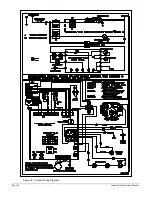

ELECTRONIC AIR CLEANER OPTION

For models with Electronic Air-Cleaner (EAC) terminals, the

Control "EAC" terminals are energized with 120 VAC when

the main blower is energized. "EAC" terminals are 1/4 inch

quick connect tabs. Use insulated quick connects when

connecting to "EAC" terminals. Limit total "EAC" current

plus main blower current to 15 amps max.

HUMIDIFIER

An optional humidifier may be installed on this furnace. The

humidifier must be field wired in circuit with the inducer

where it will be energized with 120 VAC once the inducer is

energized.

LIMIT SWITCH CIRCUIT OPEN

If the limit switch circuit opens: burners turn off, draft

inducer stays on, main blower stays on, there is no 24-volt

power on the "R" terminal and diagnostic light signal is 3

flashes.

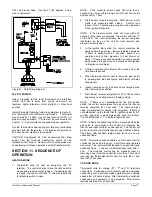

TWINNING OPTION

This furnace is capable of synchronizing blower operation

with another furnace by means of a twinning connection.

Field installation of twinning consists of connecting wires

between the “C” and “Twin” terminals of the two controls

and the “W” terminals of both controls to the thermostat call

for heat. The furnace supplying power to thermostat “R” will

supply power to the gas valves of both furnaces.

NOTE: A twin communications fault will occur if the 24

VAC supply to the twins are not in phase with each other, or

power is removed from one of the twins. While a twin fault

exists, the control will not respond to the thermostat

commands and the diagnostic light indicator will flash “5”.

NOTE: The twin furnaces may be operated in a two-stage

heat application by connecting the thermostat first stage

heat to the “W” on one control, and the second stage call

for heat to the “W” on the second control.

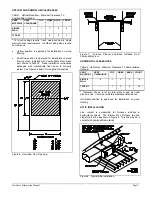

SECTION 12. INSTALLING DUCT

SYSTEM

Properly size duct system based on heat loss and heat gain

calculations to assure good heating and cooling

installations, potentially fewer call-backs and delivery of

required circulating air. Install duct system to meet current

Standard for Installations of Warm Air Heating and Air

Systems ASHRAE/NFPA 90 and local codes.

CAUTION: Failure to follow these standards could reduce

airflow or increase air leakage, resulting in reduced system

performance or furnace damage.

Design duct system so furnace will operate at a static

pressure of 0.50 inches W.C. or less. This static pressure

limitation includes the total pressure losses on both the

supply air side and the return air side of the system. Supply

side pressure loss includes the cooling coil, ducts and room

registers. Return side pressure loss includes the return

grilles and ducts. Pressure losses are calculated based on

400 cfm per ton of cooling.

SUPPLY AIR DUCT WORK

Supply air duct (plenum) connections must be at least as

big as the furnace supply opening. Attach to furnace duct

flanges. Seal supply air ductwork to furnace casing, walls,

ceilings or floors it passes through. End ductwork outside

furnace space.

On furnaces not equipped with a cooling coil, a removable

access panel that is large enough to allow viewing of the

heat exchanger should be provided in the supply duct. The

access panel should be accessible when the furnace is

installed. Seal access panel cover to prevent leaks.

If you install furnace in horizontal position with a cooling

coil, an eighteen-inch long transition between furnace and

cooling coil may be needed to allow free airflow into the

coil. Also, consult cooling coil installation instructions.

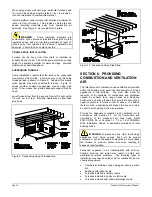

RETURN AIR DUCT WORK

When furnace is installed so that supply air ducts carry air

to areas outside the space containing the furnace, return air

must be handled by a duct(s) sealed to furnace casing and

terminating outside the space containing furnace.

WARNING

: Failure to seal return air ductwork

could allow combustion products to enter circulating air

stream resulting in injury or death by asphyxiation.

When furnace is installed in an upflow position, air delivery

above 1800 cfm requires that both sides of furnace be used

for return air or a combination of one side and bottom or

bottom only.

If bottom return air is not used, you must attach a solid

bottom closure panel to bottom return air opening. Bottom

closure panel is available from manufacturer. See Table 5

for bottom closure part numbers.