Installer’s Information Manual

Page 15

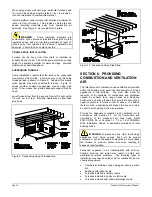

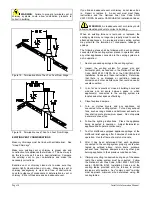

SECTION 8. SIDEWALL VENTING

In most cases, proper venting is achieved by using a

conventional vertical vent or chimney. However, it is not

uncommon to have an installation where venting through a

sidewall becomes necessary. This section contains

information on venting through a sidewall using a

mechanical (power) venter. A mechanical (power) venting

system operates at negative pressure to draw the furnace

flue products from the structure.

This furnace must not be vented with high temperature

plastic pipe.

IN THE UNITED STATES

Any mechanical (power) venting system is acceptable as

long as it has been certified by a nationally recognized

testing agency and meets all state and local codes. The

venter must be installed according to the mechanical

(power) venter manufacturer’s installation instructions. It

must be sized appropriately for the furnace and be capable

of maintaining a negative vent pressure of -0.1 to -0.5

inches W.C. in the vent pipe leaving the furnace under all

operating conditions. Because this system operates at

negative pressure, any single wall or Type B vent pipe may

be used; however, Type B-1 pipe is recommended.

In addition to the venter manufacturer’s instructions, the

furnace manufacturer requires use of a secondary safety

switch that will act to turn off the furnace in the event that

the vent pressure becomes positive. These devices are

available through the mechanical (power) venter

manufacturer.

IN CANADA

The mechanical (power) venter must be CGA certified for

each furnace model. At this time, there is one system

approved for use on this furnace in Canada. The system is

manufactured by The Field Controls Company and

includes:

•

Power Venter model SWG-4HD

•

Secondary Safety Switch model WMO-1

•

Control Kit model CK-43 or

•

Control Kit model CK-91 (for common venting with a

water heater)

The SWG-4HD is certified with this furnace for up to forty

feet and four elbows of type B-1 vent pipe. The venter must

be installed according to the mechanical (power) venter

manufacturer’s installation instructions. Adjust the power

venter to provide a negative pressure of -0.1 to -0.5 inches

W.C. in the vent pipe leaving the furnace.

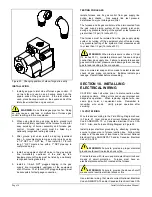

SECTION 9. INSTALLING GAS

PIPING

PREPARATION

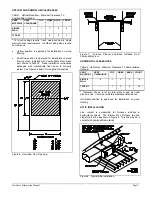

Refer to the current National Fuel Gas Code ANSI

Z223.1/NFPA 54 and/or CAN/CGA B149 Installation Codes

and local codes for gas piping requirements and sizing.

Pipe size running to furnace depends on:

•

Length of pipe

•

Number of fittings

•

Specific gravity of gas

•

Input requirements (Btu per hour) of all gas-fired

appliances attached to same main supply line.

Plan furnace gas supply piping so it will not interfere with

removal of burner assembly, front door or blower door for

servicing.

Make sure gas piping is large enough for all appliances

connected to it to operate at once without lowering gas

supply pressure. Failure to do so could cause lighting or

burning problems on any of the appliances.

Always use a pipe thread compound that is resistant to

propane (LP) gas solvent action. Sparingly apply thread

compound to all joints on male threads only, starting two

threads from the end.

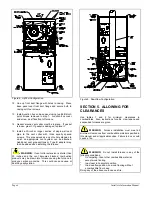

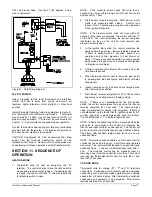

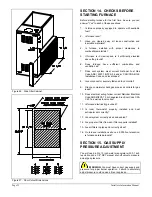

GAS ENTRY LOCATION

Choose the best gas line entry location for your installation.

This furnace has five possible gas entry locations.

•

As shipped, 1/2” NPT pipe can be attached directly to

the furnace gas control through the 1¼ by 2¾ inch

opening on the top plate.

•

Gas line entry may also be routed through the 1 ½ inch

hole in the right side of the casing by positioning a 90

degree street elbow (field supplied) on the gas valve as

shown in Figure 20.

•

For gas line entry through the knockout in the left side

of the casing, position a 90 degree street elbow (field

supplied) as shown in Figure 20. ½” NPT pipe can

now be attached to the furnace gas control from the left

side.

•

For gas line entry through either of the upper

knockouts located in the right and left sides of the

casing, remove any attached street elbow from the gas

valve, shown in Figure 20. 1/2" NPT pipe can now be

routed directly to the furnace gas control.

Some large electronic air cleaners will interfere with

incoming gas line. Install air cleaner on opposite furnace

side from gas entry or route gas pipe over top of air cleaner

through one of alternate knockouts.