Installer’s Information Manual

Page 27

Table 10. Factory Heating Speed and Temperature Rise.

*Gas Motor

**Input Size

(Btu/Hr) (H.P.)

Air

Temperature

Rise Range

(°F)

Heating

Operation

*Speed Tap/

Wire Color

40,000 / 1/4

50-80

LO/RED

40,000 / 1/3

30-60

LO/RED

60,000 / 1/4

45-75

ML/YEL

60,000 / 1/3

45-75

LO/RED

60,000 / 1/2

35-65

LO/RED

80,000 / 1/4

50-80

MH/BLUE

80,000 / 1/3

40-70

MH/BLUE

80,000 / 1/2

50-80

LO/RED

80,000 / 3/4

40-70

LO/RED

100,000 / 1/3

55-85

MH/BLUE

100,000 / 1/2

50-80

ML/YEL

100,000 / 3/4

40-70

ML/YEL

120,000 / 1/2

45-75

MH/BLUE

120,000 / 3/4

45-75

MH/BLUE

140,000 / 3/4

45-75

MH/BLUE

140,000 / 3/4

50-80

MH/BLUE

*These are initial Factory Settings.

**GAS INPUT and MOTOR HP can be found on furnace

rating plate.

Table 11. Cooling Speed Selection.

*Gas Motor

Input Size

Air Conditioning Tonnage

(Btu/Hr) (H.P.)

1.5

2

2.5

3

3.5

4

5

40,000

/ 1/4

MH

HI

--

--

--

--

--

40,000

/ 1/3

--

ML

MH

HI

--

--

--

60,000

/ 1/4

MH

HI

--

--

--

--

--

60,000

/ 1/3

--

ML

MH

HI

--

--

--

60,000

/ 1/2

--

--

--

ML

MH

HI

--

80,000

/ 1/4

HI

HI

--

--

--

--

--

80,000

/ 1/3

LO

ML

HI

HI

--

--

--

80,000

/ 1/2

--

--

--

ML

MH

HI

--

80,000

/ 3/4

--

--

--

--

ML

MH

HI

100,000

/ 1/3

LO

ML

HI

HI

--

--

--

100,000

/ 1/2

--

LO

MH

MH

HI

--

--

100,000

/ 3/4

--

--

--

LO

MH

MH

HI

120,000

/ 1/2

--

--

LO

ML

HI

HI

--

120,000

/ 3/4

--

--

--

LO

ML

HI

HI

140,000

/ 3/4

--

--

LO

ML

HI

HI

--

140,000

/ 3/4

--

--

--

LO

ML

HI

HI

*GAS INPUT and MOTOR HP can be found on furnace rating

plate.

This table only gives initial speed tap settings for installations

with ductwork static pressure of 0.5” W.C. figuring 400 CFM

per ton of air conditioning. Ductwork with higher than 0.5”

W.C. static pressure will cause reduced airflow and these

speed tap settings will not be correct. To determine correct

speed tap settings at ductwork static pressures above 0.5”

W.C., see Product Data Sheet.

SECTION 22. MEASURING DUCT

SYSTEM STATIC PRESSURE

System airflow can be determined from the Product Data

Sheet when duct system static pressure is known.

Improper airflow in heating mode may result in poor heating

performance and reduced heat exchanger life. Improper

airflow in cooling mode may cause poor cooling

performance or air-conditioning coil freeze-up.

High duct system static pressure is an indication of an

overly restrictive duct system. Static pressure in excess of

0.5 inches W.C. indicates a need for duct system redesign

to ensure proper volume of airflow.

You will need a 0 to 1 inch W.C. slope gauge with 0.01 inch

resolution and two pressure measurement taps.

Follow this procedure:

1. Open supply air registers and return air grilles. Make

sure the registers and grilles are free of obstruction

from rugs, carpets, drapes or furniture.

2. Set balancing dampers in supply duct system.

3. Check ductwork for obstructions or leaks.

4. Make sure filters are clean and in place.

5. Make sure that blower speed taps are set for proper

heating and cooling. Refer to Section 21, "Adjusting

Blower Speed." Heating speed should be set

according to Table 10. Cooling speed should be set to

meet cooling equipment requirements. See Table 11

for cooling airflow capacities at 0.5 inch W.C.

6. Place slope gauge near furnace, level and adjust scale

to read 0.00 inches W.C.

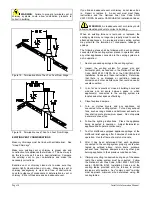

7. Insert one static pressure tap into supply air transition

duct between furnace and cooling coil or in the supply

air plenum for heating only systems. Connect this

pressure tap to positive pressure side of slope gauge.

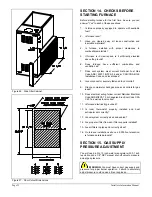

See Figure 31.

8. Insert other static pressure tap in return air plenum.

Connect this pressure tap to negative pressure side of

slope gauge. See Figure 31.

Figure 31. Measuring Duct System Static Pressure.

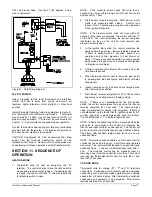

9. Start

blower.

•

Blower heating speed can be run by jumping

terminals "R" and "G" on 24-volt terminal block

located on Control.