Chapter 9

Maintenance

32708885 Geset 100

Version: 16.07.13

Page 69 of 77

GB

Retension of timing belts (Timing belt)

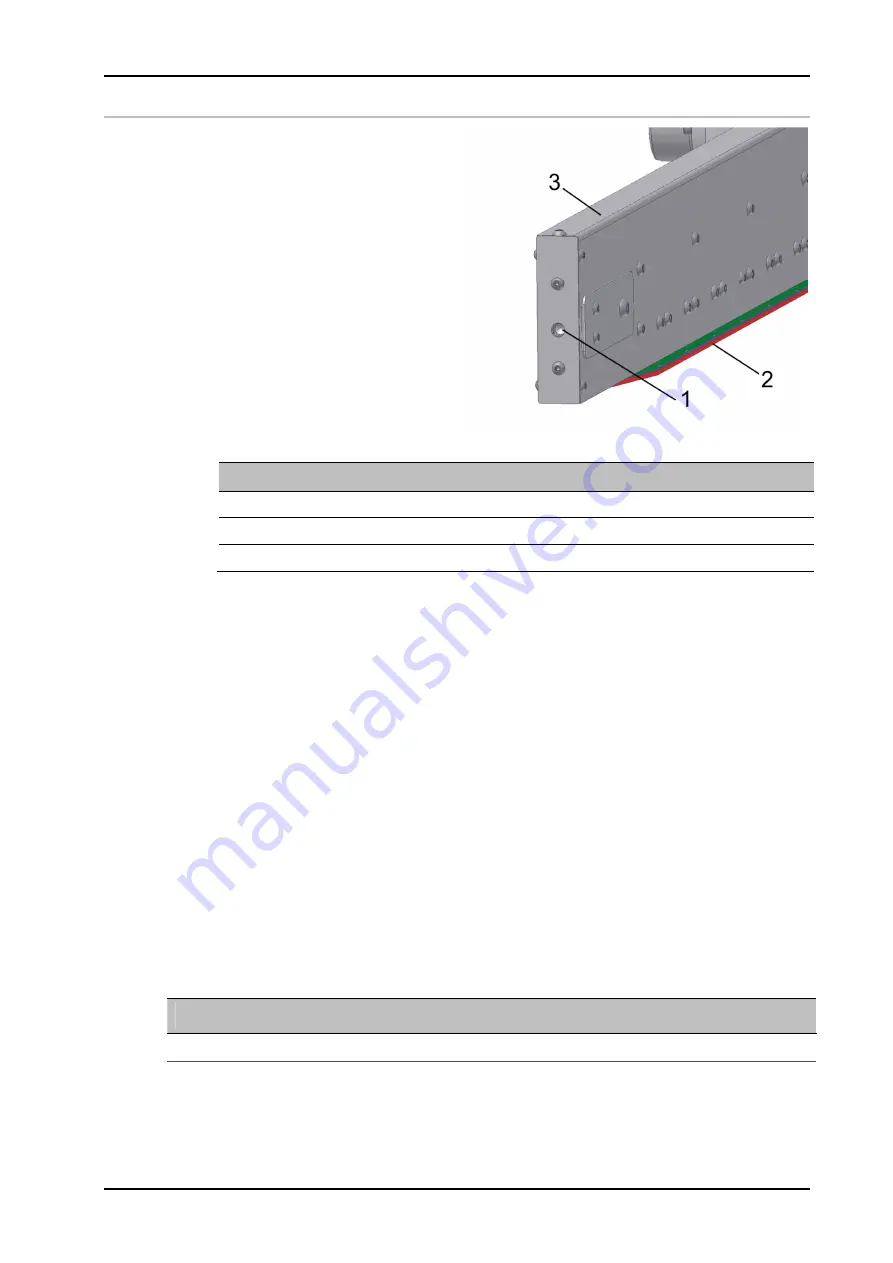

Fig. 9-2 Tense top conveyor

No.

Description

1

CLAMPING SCREW

2

TRANSPORT TIMING BELT

3

TOP CONVEYOR

The pick up of the timing belt at the drive roller is arranged by form fit of the pulley. Thus

the required belt tension is much lower than with the base conveyor. The correct tension

is reached when a skipping of the timing belt at the pulley is not possbile anymore. A belt

tension that is too high can result in damages of the deflections, bearings and timing belts.

At optimum belt tension, the belt should be adjusted in center by 90°.

Requirements

¥

No transportation of products.

¥

Labeling station is turned off.

¥

Labeling station was put into operation (see chapter “Installation and initial

startup“).

Required tool

¥

Tool: 8 mm Hexagon socket screw wrench

Instruction

Please adjust the web tension at transport timing belt as follows.

Step

Procedure

1

Tension the timing belt by means of the clamping screw.

Summary of Contents for Geset 100

Page 2: ...Blank page ...