Chapter 7

Adjustment and initial operation

32708885 Geset 100

Version: 16.07.13

Page 37 of 77

GB

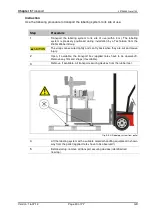

Clamp lever for adjustment or interlock

Fig. 7-2: Move clamp lever

The most simple kind of adjustment is the clam-

ping piece with clamp lever (s. Fig. 7-1, Pos. 10).

If the clamp lever can not be rotated by 360 ° due

to shortage of space, it can be easily moved by

being pulled out (s. Fig. 7-2).

Clamp levers are also used for interlock of spindle

slides (s. Fig. 7-1, Pos. 3). They will always have

to be loosened before adjustment and then they

have to be tightened again.

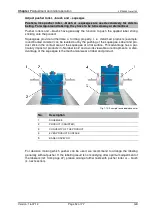

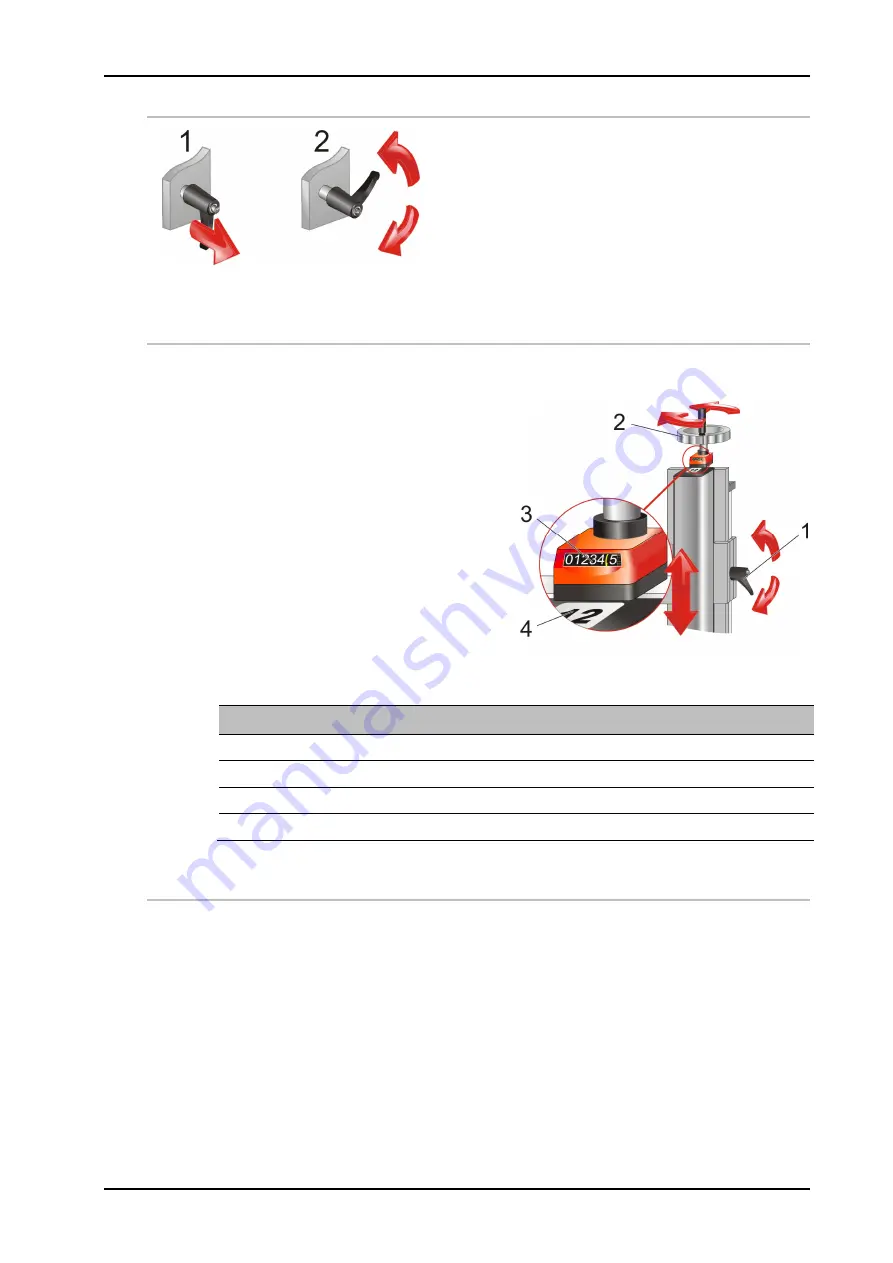

Spindle adjustments and digital counter

Depending on version, a system provides spindle adjustments with different inclinations. I.

e. at a crank rotation, the spindle slide covers a distance of resp. 2 or 4 mm

Fig. 7-3: Spindle adjustment with digital counter

No.

Description

1

CLAMP LEVER

2

CRANK

3

DIGITAL-COUNTER [mm], 1/10 [mm]

4

NUMBERING OF THE ADJUSTMENT

Record of adjustment values

Adjustments with scales or digital counters simplify the position determination and enable

thus repeatable adjustment for each product charge.

For labeling stations with scales or digital counters, we recommend to maintain a list with

„values per product“. All relevant settings should be numbered to ease the assignment of

the values.

All relevant adjustments are numbered (s. Pos 4, Fig. 7-3), to ease the alignment of

documented values. They have then only be adjusted at product change only at the

respective adjustments.

For labeling stations without scales or counters, there can maybe arranged markings at

the adjustments if applicable.

Summary of Contents for Geset 100

Page 2: ...Blank page ...