Chapter 7

Adjustment and initial operation

32708885 Geset 100

Version: 16.07.13

Page 44 of 77

GB

Step

Procedure

5

Adjust the top conveyor to the required criteria (s. section above).

6

Tighten again the interlock (clamping lever Pos. 3 Fig. 7-6).

7

Remove the product.

8

Arrange several sample labelings to check the adjustments.

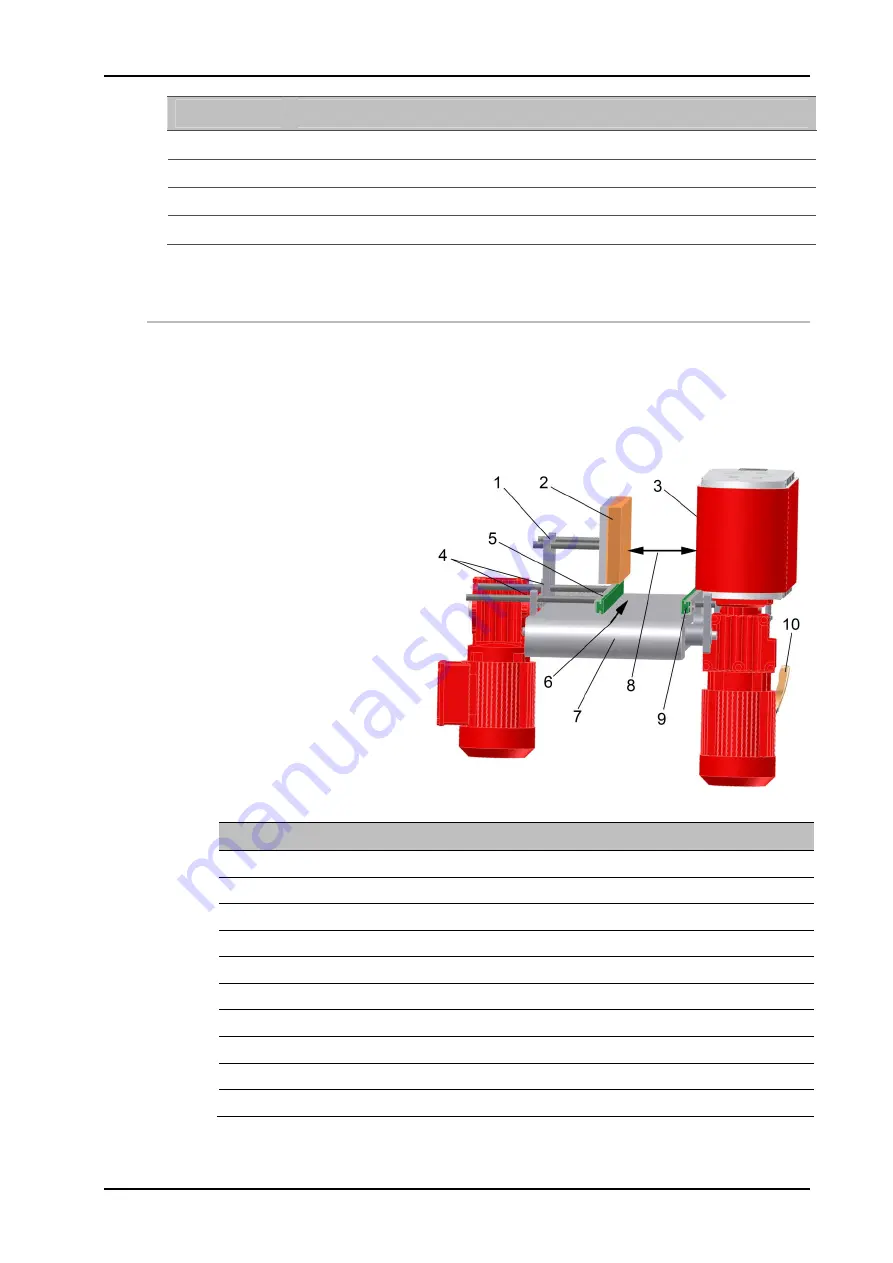

Adjust wrapping unit Geset 121

The label with the preparatory part is applied onto the product and by means of the rotati-

on and the counter pressure of the pusher plate pushed onto the product. The counter

pressure of the pusher plate and the wrapping unit (the speed of the wrapping unit is twice

as fast as the speed of the base conveyor) put the product to rotation.

Fig. 7-7: Wrapping unit

No.

Description

1

BRACKET AND POSITIONING DEVICE OF FOAM RUBBER PLATE

2

PUSHER PLATE (SPONGE RUBBER)

3

WRAPPING UNIT

4

BRACKET AND POSITIONING DEVICE OF SIDE GUIDANCE

5

SIDE GUIDANCE OUTSIDE

6

P

RODUCT TRANSPORT DIRECTION

7

BASE CONVEYOR

8

DISTANCE (PRODUCT WIDTH - APPR. 5 MM)

9

SIDE GUIDANCE INSIDE

10

CLAMPING LEVER FOR HEIGHT ADJUSTMENT

Summary of Contents for Geset 100

Page 2: ...Blank page ...