TROUBLESHOOTING

49

4. Connect an ohmmeter across the blower

proof switch and start the unit.

5. The blower proof switch should show

continuity while the blower is running.

6. If the blower proof switch does not show

continuity, remove the switch and check for

signs of blockage. If there is blockage, clean

the switch and retest.

7. If the blower proof switch shows continuity,

disconnect AC power to the unit.

8. Disconnect the 15 pin connector from the

control panel.

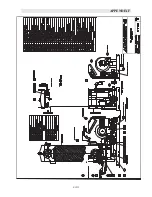

9. Referring to system schematic 161413 in

Appendix H, locate wires #17 and #24 and

check both for continuity.

10. Check the switch end of wires #17 and #24

for loose connections.

11. Check the connector end for worn pins

and/or proper pin insertion.

12. If continuity, the connector and pins are

okay, reconnect wires #17 and #24 to the

blower proof switch.

13. Reconnect the 15 pin connector to the

control panel.

14. Reconnect AC power to the unit and start

the unit.

15. If the SYSTEM FAULT LOW AIR

PRESSURE fault still persists, replace the

control panel.

8.7.4 PURGE INTERLOCKS

If the SSOV proof of closure switch or the

air/fuel valve open position switches fail to prove

closed during the start up sequence, the unit will

shut down and the Annunciator will display the

message SYSTEM FAULT, PURGE

INTERLOCKS. To determine the cause of the

fault perform the following:

1. Remove the air/fuel valve cover.

2. Clear the Annunciator and start the unit.

3. If the Annunciator displays the message

PURGE INTLK OPEN and the air/fuel valve

does not rotate, proceed to section 8.7.7.

4. If the air/fuel valve rotates to its full open

position and engages the air/fuel valve open

proving switch, and the Annunciator still

displays SYSTEM FAULT, PURGE

INTERLOCKS, proceed to section 8.7.6.

8.7.5 SSOV PROOF OF CLOSURE

SWITCH

1. Disconnect AC power to the unit.

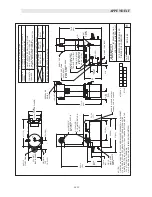

2. Loosen the two set screws securing the

safety shut-off valve actuator to the safety

shut-off valve body.

3. Rotate the actuator portion clockwise

exposing the electrical cover plate and

tighten the two previously loosened set

screws.

4. Remove the electrical cover plate exposing

the control wiring

5. Referring to the system schematic 161413 in

Appendix H, remove wires #21 and #22 from

the proof of closure switch.

6. Connect an ohm meter across the NC,

normally closed, and the C, common,

terminals.

7. The switch should show continuity. If it does

show continuity proceed to step 16.

8. If the switch does not show continuity,

remove the actuator from the valve body.

9. Looking at the actuator from the bottom,

push on the lever closest to the bottom of

the actuator.

10. Observe the ohm meter while pushing on

the lever. Pushing downward on the lever

should make continuity. Releasing the lever

should break continuity.

.

11. If continuity makes and breaks, slightly bend

the arm toward the bottom of the actuator.

12. Reset the actuator onto the valve body while

observing the ohm meter.

13. If continuity is now okay, reconnect wires

#21 and #22, replace the electrical cover

plate and reassemble the actuator to the

valve body.

Summary of Contents for AERCO KC Series

Page 51: ...TROUBLESHOOTING 41...

Page 65: ...APPENDIX C ix...

Page 72: ...APPENDIX F xvi...

Page 74: ...APPENDIX F xviii...

Page 76: ...APPENDIX G xx...

Page 77: ...APPENDIX G xxi...

Page 78: ...APPENDIX H xxii...

Page 79: ...APPENDIX H xxiii...

Page 80: ...APPENDIX H xxiv...