BA E16 en* 1.0 * E16_10_900.fm

9-13

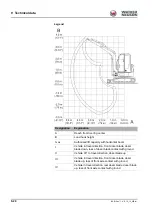

Technical data 9

• Reduce vibration to a minimum during long work cycles or during

vehicle operation over long distances:

- Use a vehicle with a suspension system (for example on the operator

seat).

- Enable the hydraulic oscillation damping if the vehicle is equipped

with tracks.

- If the vehicle is not equipped with hydraulic oscillation damping,

reduce your speed to avoid bumps and jolts.

- Load the vehicle on a truck or trailer to move between job sites.

• Other risk factors can affect drive comfort negatively. The following

measures can improve drive comfort:

- Adjust the operator seat and the control elements to a relaxed body

posture.

- Adjust the rearview mirrors to ensure optimal visibility so you can

adopt an upright seating position.

- Provide breaks to avoid sitting for long periods.

- Do not jump off the cabin.

- Picking up and raising loads repeatedly must be limited to a

minimum.

Reference:

The vibration values and calculations are based on the indications made

in ISO/TR 25398 Mechanical Vibrations – Guidelines for assessment of

exposure to whole-body vibration during operation of earth moving

vehicles.

The harmonized data comply with measurements made by international

institutes, organizations and manufacturers. This publication offers

information on the calculation of whole-body vibrations for operators of

earth moving vehicles. This method is based on vibration measurements

under real operating conditions for all vehicles. Read the original

guidelines. This chapter summarizes part of the legal regulations.

However, its aim is not to replace the original references. Other parts of

this document are based on information of the United Kingdom Health and

Safety Executive.

For more information on vibration, refer to Directive 2002/44/EC of

European Parliament and Council on minimum health and safety

requirements regarding exposure of workers to risks arising from physical

agents (vibration).

Your Wacker Neuson dealer provides information on other vehicle

functions reducing vibration and on safe operation.

Summary of Contents for ET35

Page 14: ...1 8 BA E16 en 1 0 E16_10_100 fm 1 Foreword Notes...

Page 46: ...3 8 BA E16 en 1 0 E16_10_300 fm 3 Introduction Warning labels Fig 9 symbolic representation...

Page 64: ...3 26 BA E16 en 1 0 E16_10_300 fm 3 Introduction Notes...

Page 194: ...6 8 BA E16 en 1 0 E16_10_600 fm 6 Transportation Notes...

Page 252: ...8 8 BA E16 en 1 0 E16_10_800 fm 8 Malfunctions Notes...

Page 292: ...9 40 BA E16 en 1 0 E16_10_900 fm 9 Technical data 9 15 Dimensions ET35 symbolic representation...

Page 294: ...9 42 BA E16 en 1 0 E16_10_900 fm 9 Technical data EZ36 symbolic representation...

Page 296: ...9 44 BA E16 en 1 0 E16_10_900 fm 9 Technical data Notes...

Page 300: ...S 4 BA E16 en 1 0 E16_10_3SIX fm...