BA E16 en* 1.0 * E16_10_700.fm

7-7

Maintenance 7

Maintenance schedule of Lehnhoff mechanical quickhitch system

Other maintenance intervals (Wacker Neuson service center):

• Every 250 operating hours or semi-annually (MS03)

• Every 500 operating hours or annually (MS03)

For additional details contact a Wacker Neuson service center.

L

L

L

M

M

G

H

H

Y

L

L

N

N

K

K

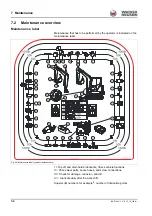

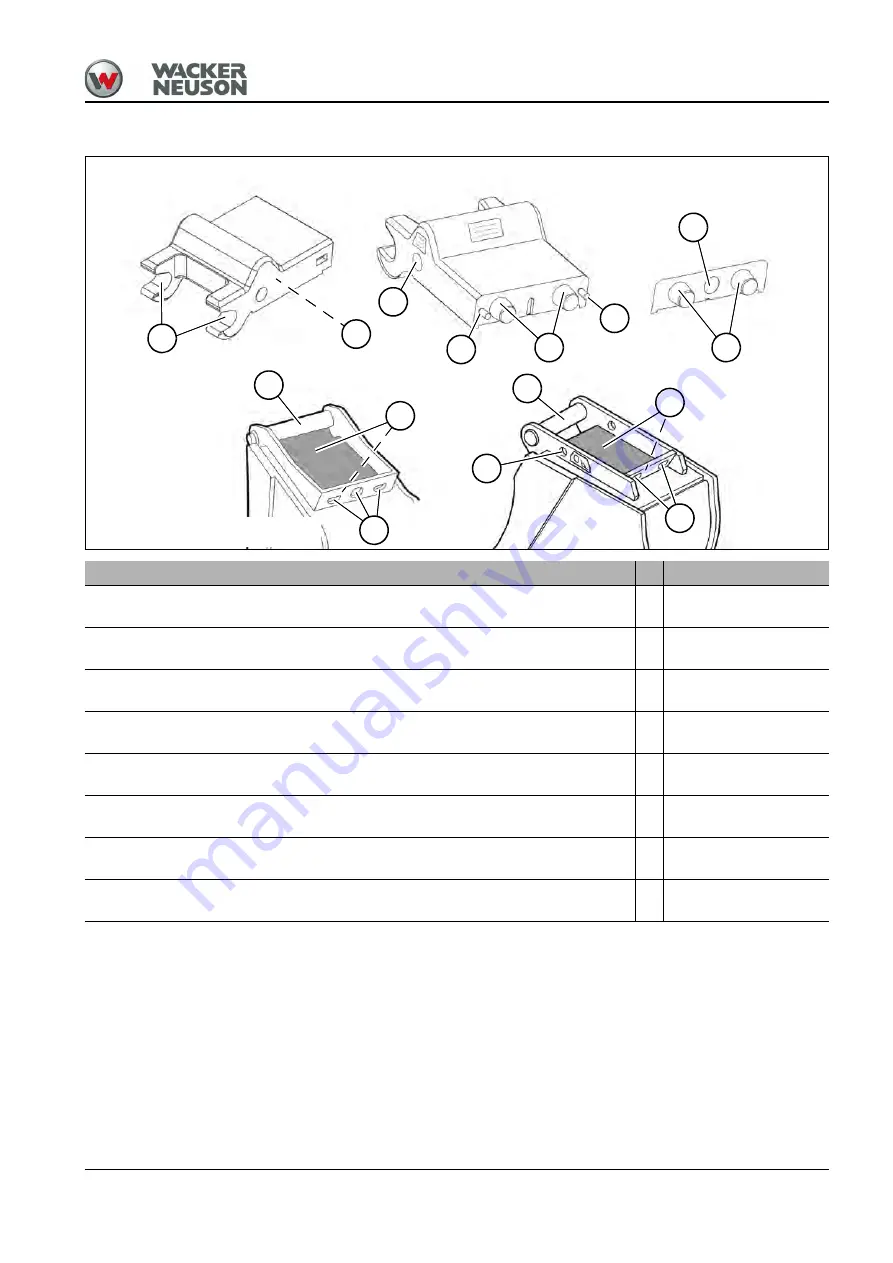

Fig. 262 (symbolic representation)

Quickhitch maintenance MS03/MS08/MS10 (operator)

Interval

1

Perform visual inspection of the quickhitch system

--

10 hours of operation/

daily

Clean bolt guide

G

50 hours of operation/

weekly

Clean the bolt contact surface

H

50 hours of operation/

weekly

Clean bottom side of the quick coupler system

Y

50 hours of operation/

weekly

Clean contact surfaces of the attachment

K

50 hours of operation/

weekly

Clean the opening for the socket wrench and bores of the attachment support

L

50 hours of operation/

weekly

Clean bolt attachment support

M

50 hours of operation/

weekly

Clean centering pins (only MS10)

N

50 hours of operation/

weekly

1.

For time specifications: the first achieved time specification is decisive. If the situation requires it, perform maintenance if necessary, even if the maintenance

interval has not yet been reached.

Summary of Contents for ET35

Page 14: ...1 8 BA E16 en 1 0 E16_10_100 fm 1 Foreword Notes...

Page 46: ...3 8 BA E16 en 1 0 E16_10_300 fm 3 Introduction Warning labels Fig 9 symbolic representation...

Page 64: ...3 26 BA E16 en 1 0 E16_10_300 fm 3 Introduction Notes...

Page 194: ...6 8 BA E16 en 1 0 E16_10_600 fm 6 Transportation Notes...

Page 252: ...8 8 BA E16 en 1 0 E16_10_800 fm 8 Malfunctions Notes...

Page 292: ...9 40 BA E16 en 1 0 E16_10_900 fm 9 Technical data 9 15 Dimensions ET35 symbolic representation...

Page 294: ...9 42 BA E16 en 1 0 E16_10_900 fm 9 Technical data EZ36 symbolic representation...

Page 296: ...9 44 BA E16 en 1 0 E16_10_900 fm 9 Technical data Notes...

Page 300: ...S 4 BA E16 en 1 0 E16_10_3SIX fm...