VE272SFS Roll Grooving Tool

17

7.

Using the hand wheel, advance the sta-

bilizer roller inward until the roller lightly con-

tacts the pipe. Tighten the stablizer locking

handle. Refer to Figures 3 and 4 on this page

for proper positioning.

8.

Complete all adjustments and groove

the pipe. Refer to the "Grooving Operation"

section, starting on page 20. Observe the

stabilizer roller while grooving. It should

remain in contact with the pipe, and the pipe

should rotate smoothly without swaying from

side to side. If the pipe is not rotating smoothly

or is swaying from side to side, adjust the sta-

bilizer roller further inward. Continue the

grooving operation and make further adjust-

ments, as necessary. DO NOT adjust the sta-

bilizer too far inward, since it will skew the

pipe to the left and off center, resulting in ex-

cessive pipe-end flare.

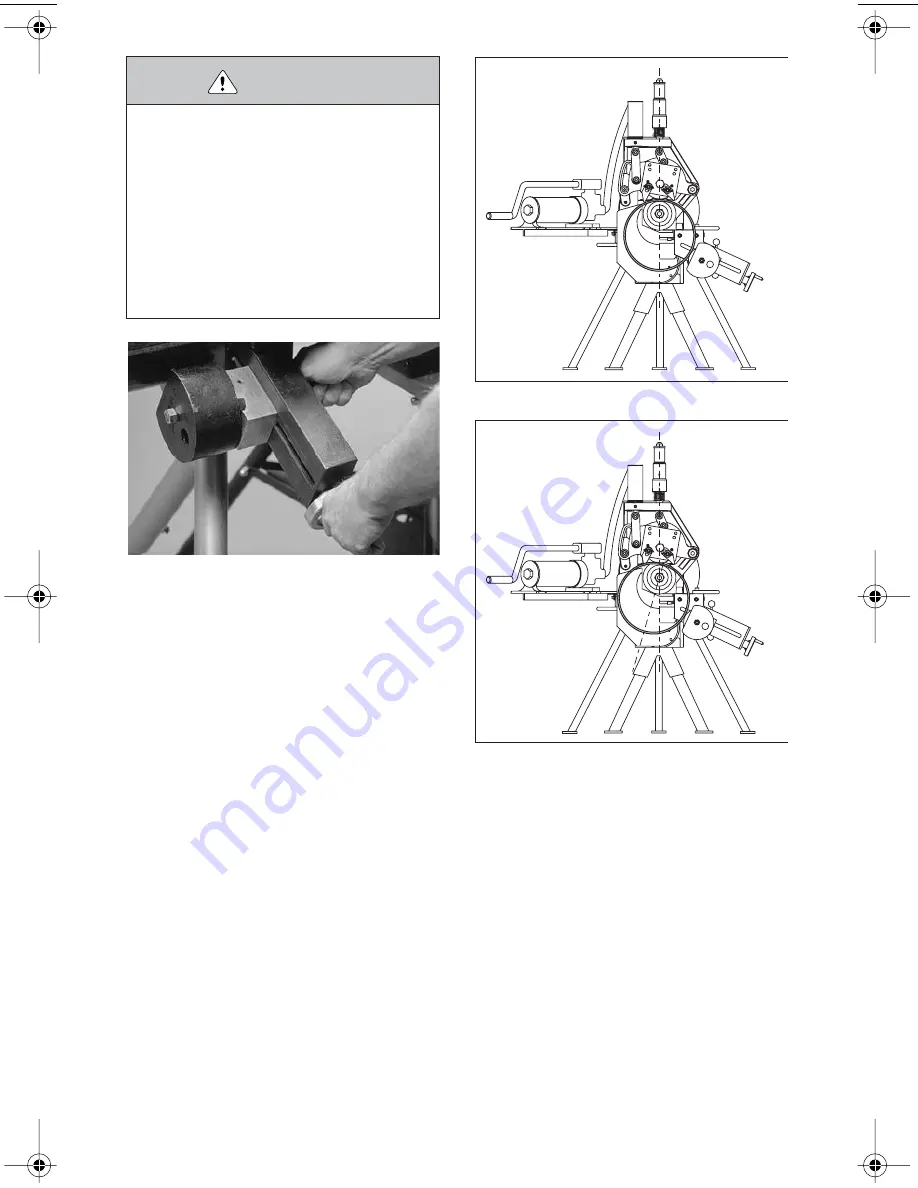

Figure 3 - “CORRECT”

Figure 4 - “INCORRECT”

CAUTION

• DO NOT adjust the stabilizer to push the pipe to the

left and off center from the rolls. Increased pipe-end

flare and shortened roll life will result if the pipe is

pushed to the left and off center.

• Assembly of couplings on pipe that exceeds the

maximum allowable flare dimension may prevent

proper pad-to-pad assembly of coupling housings

and may cause gasket distortion/damage.

Failure to prepare pipe in accordance with all instruc-

tions may cause joint failure, resulting in personal

injury and/or property damage.

TM-VE272SFS 3776 Rev_B.fm Page 17 Friday, December 3, 2004 12:10 PM

Summary of Contents for VE272SFS

Page 2: ......