25

4 Mounting

VEGAPULS 67 • Profibus PA

36533-EN-170405

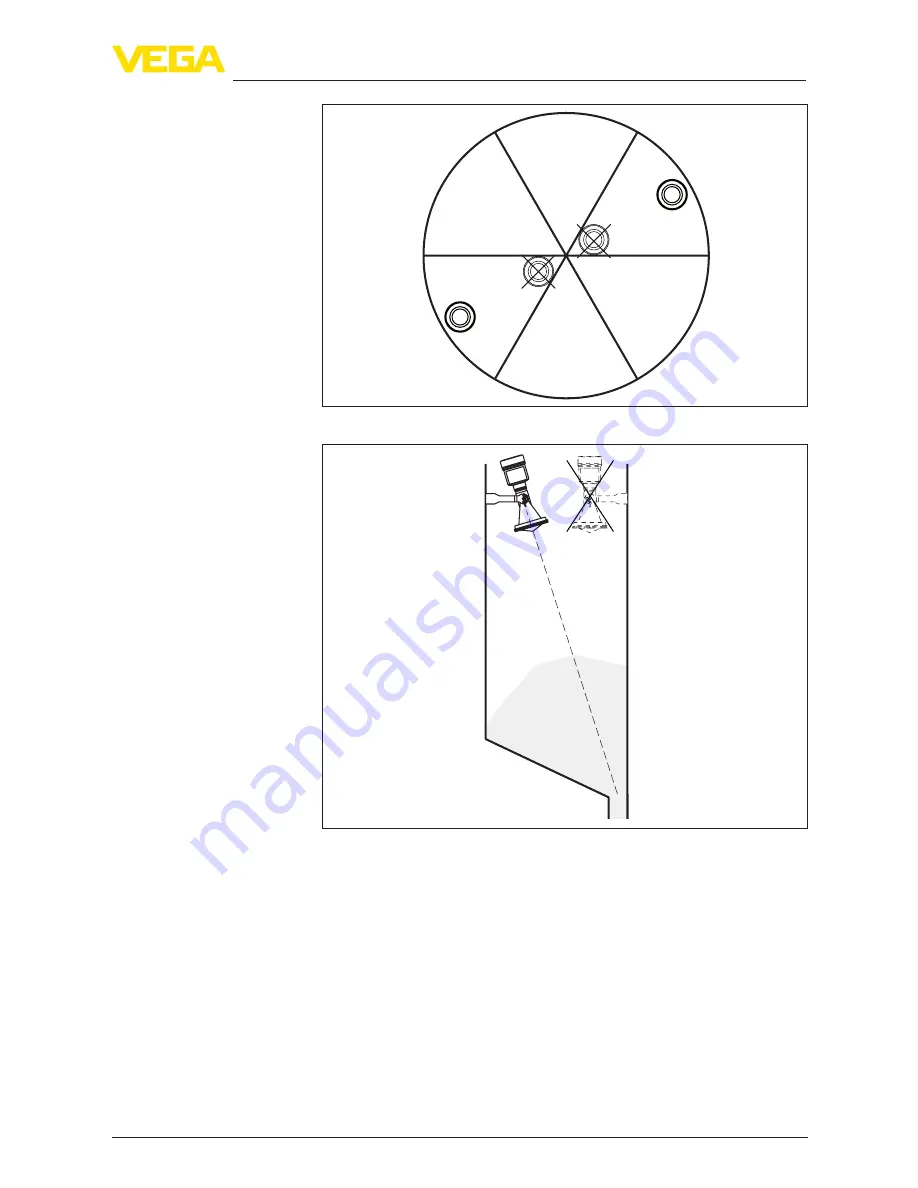

Fig. 20: Installation and orientation in multiple chamber silos

Fig. 21: Installation and orientation in multiple chamber silos

Air rinsing is useful for avoiding buildup, particularly when there is

strong condensation. Since VEGAPULS 67 has no direct rinsing air

connection, a separate rinsing air connection must be provided in

the mounting socket. By inclining this connection towards the top, a

particularly effective cleaning of the antenna cover is achieved.

Air rinsing