Installation and maintenance instructions ecoTEC plus 937 0020031552_06

49

We recommend the conclusion of an inspection and

maintenance contract with an approved company or

installer.

The inspection serves to determine the actual condition

of the respective boiler and compare it with the speci-

fied condition. This is done by measuring, checking and

observing.

Maintenance is required in order to eliminate any devia-

tions of the actual condition from the specified condi-

tion.

This normally is done by cleaning, adjustment and, if

neces-sary, replacing individual components that are

subject to wear.

You must carry out an annual inspection of the

Vaillant ecoTEC.

It is possible to perform a quick, accurate inspection

without removing components by requesting data from

the DIA system, carrying out the simple visual checks

indicated in Table 8.2 and performing a flue gas meas-

urement.

The maintenance intervals (at least once every 5 years)

and their scope are determined by the heating engineer

based on the condition of the boiler found during the

inspection.

All inspection and maintenance work should be per-

formed in the order specified in Table 8.2.

a

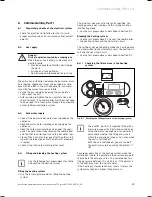

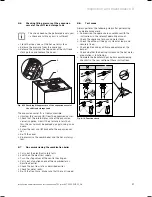

Danger!

Possible poisoning and burning by escaping

hot flue gases!

It is possible that hot flue gases escape and

could result in poisoning or burning, if the

boiler is operated

-

without a completely installed air/flue

gas duct

- with an opened air/flue gas duct

-

with internal leakages and an opened

front casing.

Operate the boiler

- for commissioning

- for testing purposes

- in continuous mode

only with closed front casing and com-

pletely mounted and closed air/flue gas

duct.

>

8.1.1

General inspection and maintenance

instructions

To ensure the faultless operation, long term availability

of all functions and long working life of your Vaillant

boiler and to prevent modifications to the approved

series status only genuine Vaillant spare parts must be

used when carrying out inspection, maintenance and

repair work.

For an overview of the available original Vaillant spare

parts, contact the Vaillant sales office on

01634 292310.

During any inspection and maintenance or after change

of parts of the combustion circuit, the following must be

checked:

The appliance has been installed in accordance

with the relevant installation instructions.

The integrity of the flue gas installation and flue

seals is in accordance with the relevant flue instal-

lation instructions enclosed.

Visual, the integrity of the boiler combustion cir-

cuit and relevant seals.

The gas inlet working pressure at maximum rate as

described in section 6.9.3.

The gas flow rates as described in section 6.9.2.

Correctness of electrical, water and gas connec-

tions.

Correctness of the water pressure.

The condition of the whole system, in particular

the condition of radiator valves, evidence of leak-

age from the heating system and dripping taps.

Correct any faults before proceeding.

8.1.2 Safety

instructions

a

Danger!

Danger of life and limb by electric shock!

The supply terminals of the boiler are under

mains voltage even if the boiler main switch

is off.

Don’t touch the supply terminals.

Protect the electronic box from any water

or spray.

Before working on the boiler, turn off the

power and secure against restart.

i

If it is necessary to keep the electricity to the

boiler switched on for certain inspection and

maintenance, this is indicated in the description

of the maintenance task.

–

–

–

–

–

–

–

–

>

>

>

>

Inspection and maintenance 8

Summary of Contents for ecoTEC plus 937

Page 1: ...For the heating engineer Installation and maintenance instructions GB IE ecoTEC plus 937 VUI...

Page 74: ...74 Installation and maintenance instructions ecoTEC plus 937 0020031552_06...

Page 76: ...76 Installation and maintenance instructions ecoTEC plus 937 0020031552_06...

Page 77: ...Installation and maintenance instructions ecoTEC plus 937 0020031552_06 77...

Page 78: ......

Page 79: ......

Page 80: ...0020031552_06 GBIE 102010 Subject to alterations...