Installation and maintenance instructions ecoTEC plus 937 0020031552_06

15

It is possible to mount onto a wall made of flammable

material if the regulations of the Local Authority and

the legal building regulations are fulfilled. In this case

however, the unit would have to be mounted in a spe-

cially made enclosure. (You can also use an existing

cabinet or existing enclosure as long as it can be modi-

fied accordingly to suit the new application.) Further

details concerning the fundamental characteristics when

modifying existing cabinets or enclosures, including the

requirements for ventilation, are described in BS 6798.

i

If the boiler is to be installed in a half-tim-

bered house, the installation must be under-

taken in accordance with the Institute of Gas

Engineers Publication IG/UP/7 Edition 2 „Gas

installations in timber framed and light steel

framed buildings“.

i

If the boiler is to be installed in an airing

cupboard it is not required to separate the

boiler with a non-combustible partition. How-

ever installation and servicing clearances

must be maintained, and the appliance kept

clear of any clothing.

Please note the following instructions before choos-

ing where to install the boiler:

b

Caution!

Possible material damage due to an unsuit-

able installation location.

The appliance may be damaged by frost,

aggressive vapours or dust.

Do not install the appliance in rooms that

are susceptible to frost.

Do not operate the appliance in rooms with

aggressive vapours or dust unless it is

operated in way that does not depend on

the room air.

Make sure that, when selecting the installation location

and when operating the unit, the combustion air is free

from chemical substances which contain fluorine, chlo-

rine, sulphur etc. Sprays, solvents and cleaning agents,

paints, adhesives etc.can contain substances of this type

which can cause corrosion in the flue gas system, in the

worst case even if the unit is operated as an open vent

appliance. Particularly in hairdressing salons, lacquering

and finishing, cleaning facilities, the appliance must be

operated independent of the ambient air! Otherwise, a

separate installation room is required to guarantee that

the combustion air supply is free from the afore men-

tioned substances.

>

>

>

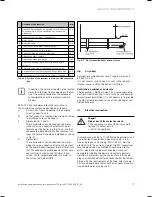

4.3 Gas

supply

The gas provider must guarantee the availability of an

adequate gas supply. The connection of a gas meter in

the supply line is only permitted when carried out by the

gas provider and a company appointed by him.

If there is an existing gas meter you must check that it

is suitable for the required gas flow rate.

Installation pipes should be fitted in accordance with

BS 6891. In IE in accordance with the current issue of

IS 813. The pipework between the gas meter and the

combi boiler must be of an appropriate size. Do not use

any pipes that are smaller than the connection to the

combi boiler (22 mm). The entire installation must be

checked for leaks and purged in accordance with

BS 6891.

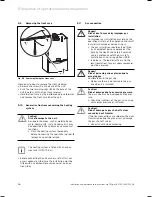

4.4

Flue pipe

a

Danger!

Risk of personal injury and material dam-

age as a result of malfunctions.

Malfunctions may be caused by using acces-

sories that are not specified in the Vaillant

installation manual for air/exhaust ducts.

Only use genuine Vaillant air/exhaust

ducts.

Vaillant appliances are only system-certified if genuine

Vaillant air/exhaust ducts are used.

The CE mark is only valid if the appliance is operated

with Vaillant air/exhaust ducts.

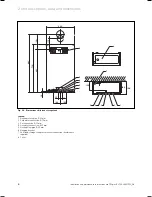

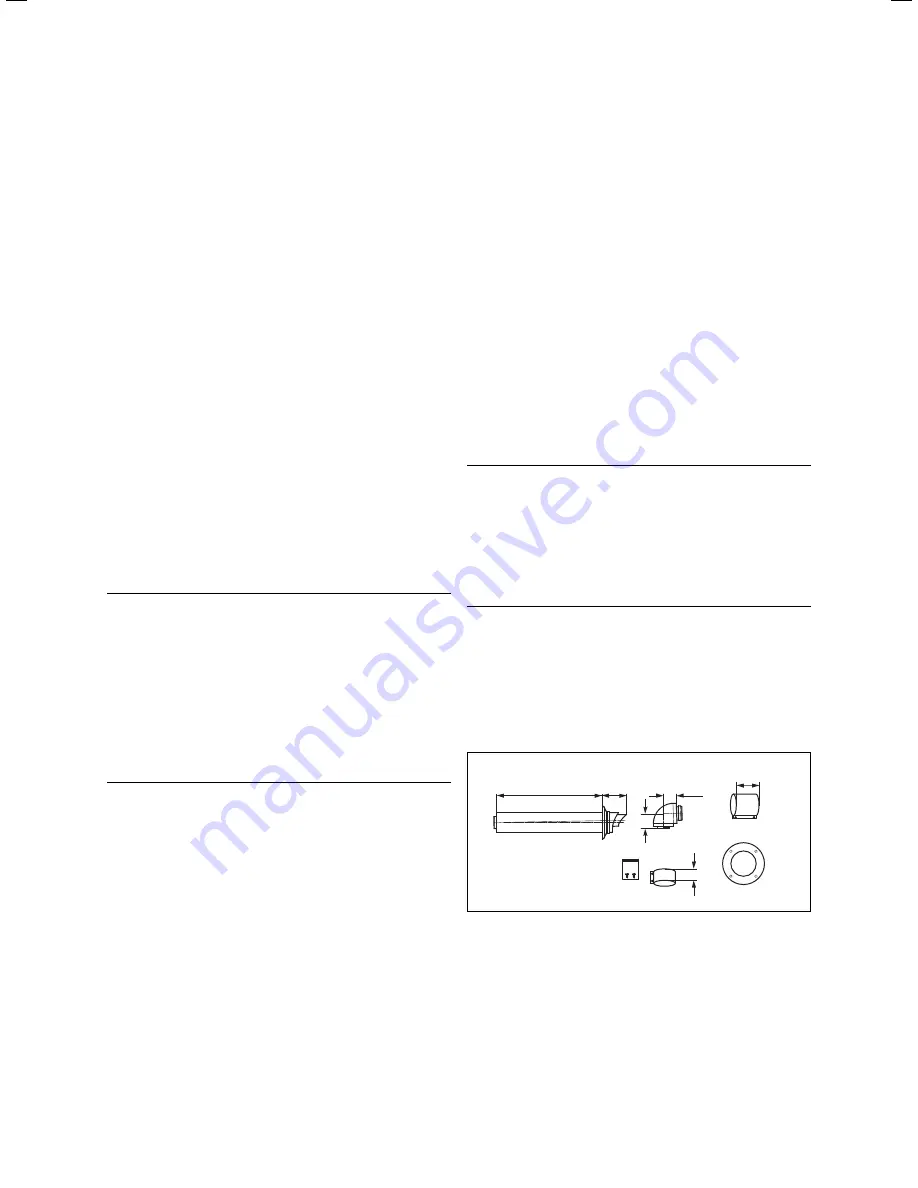

4.4.1

100 mm standard flue duct

667

87

65

30

74

48

Fig. 4.2 Item No. 303 933

A 100 mm standard flue duct (Item No. 303 933) is

available. Further information can be obtained from the

installation instructions for the flue duct.

Extensions are available to increase this length to a

maximum of 5.5 m. 87° elbows and 45° bends are also

available to increase the flexibility during installation.

>

General requirements 4

Summary of Contents for ecoTEC plus 937

Page 1: ...For the heating engineer Installation and maintenance instructions GB IE ecoTEC plus 937 VUI...

Page 74: ...74 Installation and maintenance instructions ecoTEC plus 937 0020031552_06...

Page 76: ...76 Installation and maintenance instructions ecoTEC plus 937 0020031552_06...

Page 77: ...Installation and maintenance instructions ecoTEC plus 937 0020031552_06 77...

Page 78: ......

Page 79: ......

Page 80: ...0020031552_06 GBIE 102010 Subject to alterations...