Installation and maintenance instructions ecoTEC plus 937 0020031552_06

19

Jenaqua 110

Sentinel X 100

Sentinel X 200

Additives for frost protection intended to remain per-

manently in the system

Fernox Antifreeze Alphi 11

Sentinel X 500

Inform the operator of the necessary measures in

case you have used any of these additives.

Inform the operator of the required procedures for

frost protection.

Observe the applicable national regulations and tech-

nical standards for the treatment of filling and top-up

water.

Provided the national regulations and technical stand-

ards do not specify any higher requirements, the follow-

ing applies:

You must treat the heating water

if the total volume of filling and top-up water

exceeds thrice the nominal volume of the heating

system over the service life of the system

or

if the limits given in the following tables are not

adhered to.

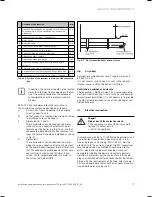

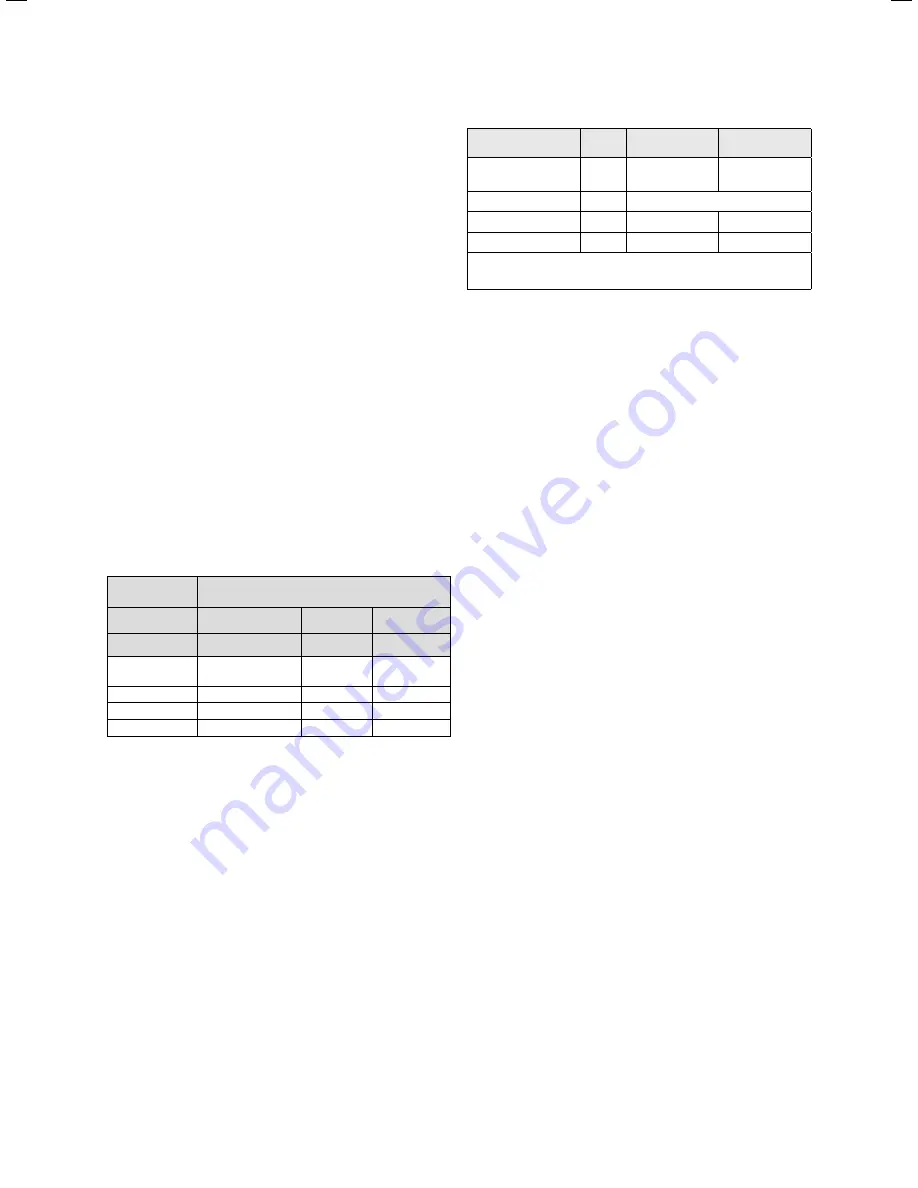

Total heating

output

Total hardness for the smallest boiler heating

surface

2)

at 20 l/kW

> 20 l/kW

< 50 l/kW

> 50 l/kW

kW

mol/m

3

mol/m

3

mol/m

3

50

No requirement or

3

1)

2

0,02

50 to

200

2

1,5

0,02

200 to

600

1,5

0,02

0,02

600

0,02

0,02

0,02

1) with systems equipped with wall-hung boiler and systems with

electric heating elements

2) of the specific system volume (nominal capacity in litres/heat-

ing output; in case of multiple boiler systems the lowest indi-

vidual heating output should be used)

These data only apply up to 3x the system volume for filling

and top-up water. Once this triple system volume is exceeded,

the water will have to be treated exactly the same as in case

of exceeding the limit values given in table 4.4 (softening,

desalination, hardness stabilisation and desludging).

Table 4.3 Guidelines for the heating water: Water hardness

–

–

–

–

–

>

>

>

>

–

–

Heating water

qualities

Unit

Low-salt

saline

Electric conductivity

at 25 °C

S/cm

100

100-1500

Appearance

Free of sedimentary substances

pH-value at 25 °C

8,2-10,0

1)

8,2-10,0

1)

Oxygen

mg/L

0,1

0,02

1) With aluminium and aluminium alloys, the ph value range is

restricted from 6.5 to 8.5.

Table 4.4 Guidelines for heating water: Salinity

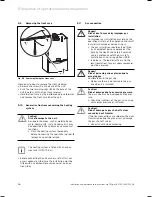

4.8.3 Pressure

relief

valve

The boiler is equipped with a pressure relief valve. This

safety device is required for all sealed central heating

systems, is preset to 3 bar and is fitted with a 15 mm

compression connection for the discharge pipe, whose

diameter must not be less than 15 mm. The pressure

relief valve must not be used for draining purposes.

4.8.4 Pressure

gauge

The pressure gauge is fitted to the boiler in the factory

and indicates the pressure of the primary circuit, to

make filling and testing easier.

General requirements 4

Summary of Contents for ecoTEC plus 937

Page 1: ...For the heating engineer Installation and maintenance instructions GB IE ecoTEC plus 937 VUI...

Page 74: ...74 Installation and maintenance instructions ecoTEC plus 937 0020031552_06...

Page 76: ...76 Installation and maintenance instructions ecoTEC plus 937 0020031552_06...

Page 77: ...Installation and maintenance instructions ecoTEC plus 937 0020031552_06 77...

Page 78: ......

Page 79: ......

Page 80: ...0020031552_06 GBIE 102010 Subject to alterations...