Installation and maintenance instructions ecoTEC plus 937 0020031552_06

39

6 Commissioning,

Part

I

6.1

Preparatory checks of the electrical system

Check the electrical installation for short circuits,

proper earthing and earth resistance and for correct

polarity.

6.2 Gas

supply

a

Danger!

Risk of explosion caused by escaping gas.

When the gas line is bled, gas may leak and

possibly ignite.

Provide adequate ventilation whilst doing

the work.

Extinguish all naked flames.

Do not smoke while bleeding the gas line.

The entire gas installation including the gas meter must

be inspected, checked for leaks and purged in accord-

ance with BS 6891. In the Irish Republic (IE) in accord-

ance with the current version of IS 813.

Purge the gas supply by opening the gas isolator

valve under the unit.

After purging re-tighten the gas isolator valve and

check for leaks. (The combi boiler itself does not need

to be purged.) This takes place through the automatic

burner ignition monitoring system.

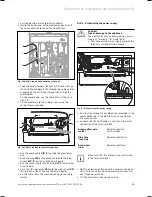

6.3 Cold

water

supply

Open all the domestic hot water taps supplied by the

appliance.

Open the mains water isolating valve supplying the

appliance.

Open the cold water isolating valve under the appli-

ance. The water then flows through the combi boiler

and the shift load storage tank to the hot water taps.

Close all the hot water taps one after the other start-

ing with the lowest one until the hot water pipework

is vented.

Check all hot and cold water pipes for leaks.

6.4

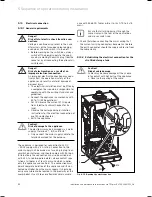

Filling and bleeding the heating system

i

Use the following test programmes for filling

and venting the heating system:

Filling the heating system

Use the test programme P.6 for filling the heating

system:

>

>

>

>

>

>

>

>

>

>

>

>

The diverter valve moves to the central position, the

heating pump is not running and the unit does not go

into heating mode.

Use the test programme as described in Section 9.2.

Bleeding the heating system

Use the test programme P.0 to vent the combi boiler,

the heating system and the hot water circuit.

The unit does not go to heating mode, the heating pump

runs intermittently and alternately vents the heating cir-

cuit and the hot water circuit.

Use the test programme as described in Section 9.2.

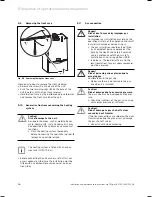

6.4.1

Checking the fill pressure in the heating

system

bar

bar

1

2

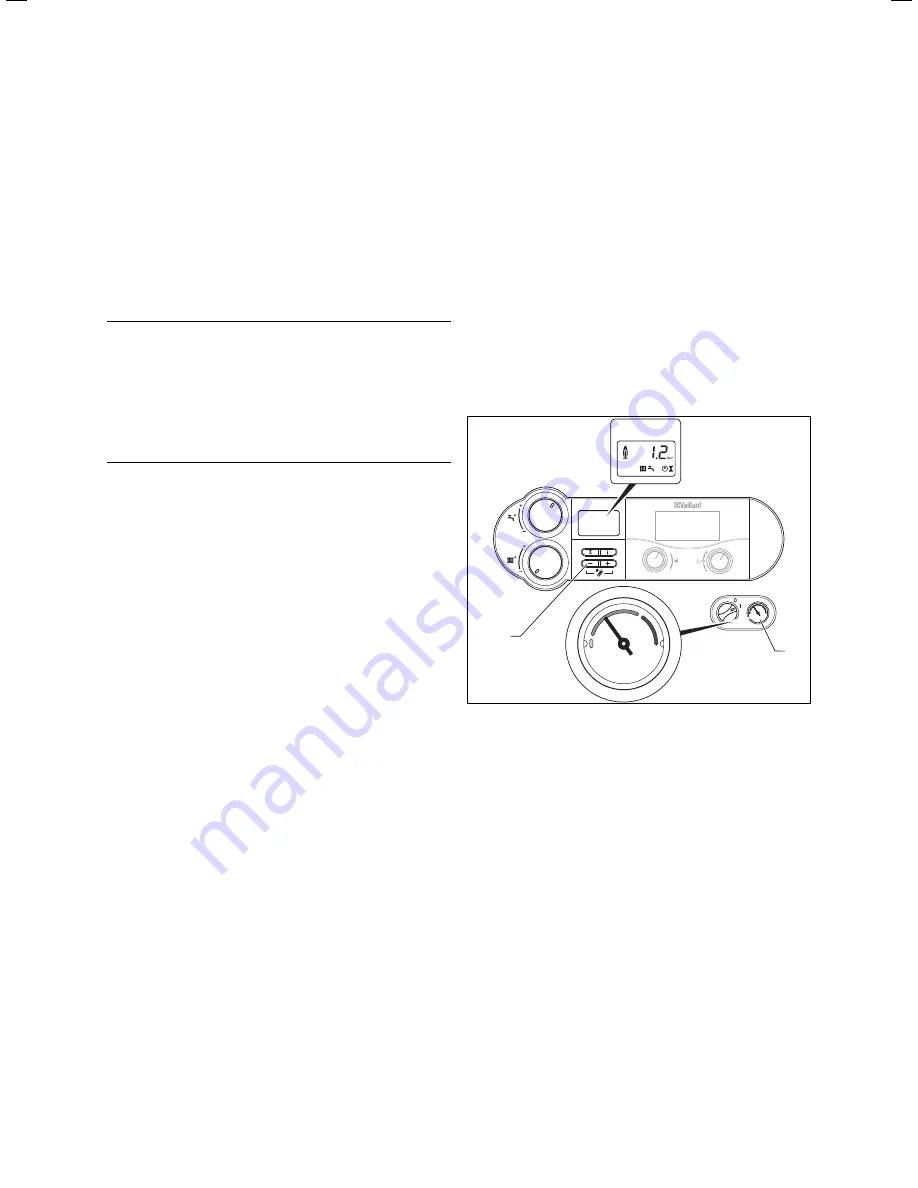

Fig. 6.1 Checking the filling pressure of the heating system

i

The ecoTEC plus 937 is supplied fitted with a

pressure gauge and a digital pressure display.

Using the pressure gauge you can perform a

quick check whether the filling pressure is

within the prescribed range or not, even when

the unit is switched off.

With the unit switched on, you can read off

the exact pressure by pushing the button "

-

"

(

2

).

For proper operation of the heating system, when the

installation is cold, the pointer on the pressure gauge (

1

)

should be in the dark-grey area. This corresponds to a

filling pressure between 1.0 and 2.0 bar. If the pointer is

in the light grey area, top up with water.

If the heating system extends over several storeys, the

system may require a higher filling pressure.

>

>

>

Commissioning, Part I 6

Summary of Contents for ecoTEC plus 937

Page 1: ...For the heating engineer Installation and maintenance instructions GB IE ecoTEC plus 937 VUI...

Page 74: ...74 Installation and maintenance instructions ecoTEC plus 937 0020031552_06...

Page 76: ...76 Installation and maintenance instructions ecoTEC plus 937 0020031552_06...

Page 77: ...Installation and maintenance instructions ecoTEC plus 937 0020031552_06 77...

Page 78: ......

Page 79: ......

Page 80: ...0020031552_06 GBIE 102010 Subject to alterations...