2NM/2NX/2NY/2NZ/2P0/2P6-1

1-3-62

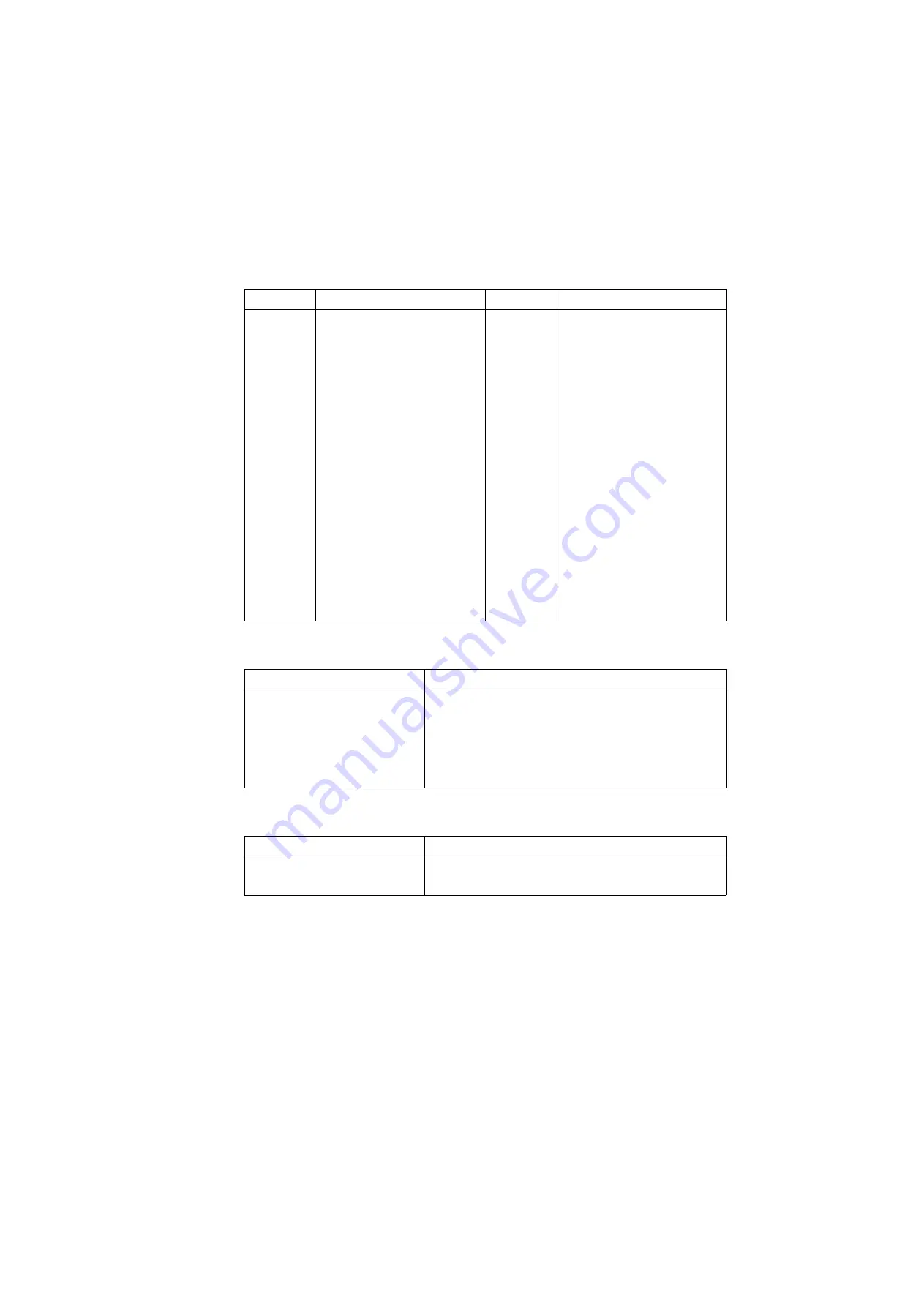

Error Codes

Codes

Description

Codes

Description

e0001

HDD is unavailable.

t0001

Fatal error.

e0002

USB memory is unavailable.

t0002

Error in processing the network.

e0003

The file to import does not exist

in the USB.

t0003

An illegal parameter error.

e0004

Reading from the USB has

failed.

t0004

Insufficient resource.

e0005

Unmounting USB has failed.

t0005

Communication error.

e0006

Moving or renaming the file has

failed.

t0006

Error in processing communica-

tion.

e0007

Opening the file has failed.

t0007

Login error.

e0008

Closing the file has failed.

t0008

External error.

e0009

Error in reading the file.

t0009

Authentication error.

e000A

Copying the file has failed.

t000A

Request error.

e000B

Opening the directory has failed.

t000B

Error due to the server.

e00C

Creating a working directory has

failed.

t00C

Error due to the client.

e00D

Deleting a working file has failed.

Setting: [Information]

1. Select the item.

Display

Description

Agent ID

Agent ID

Agent Type

Agent Type

Model

model name

Serial No

Serial number

Offline

TDRS connection state

Setting: [On/Off Config]

1. Select the item.

Display

Description

On

Enable TDRS

Off

Disable TDRS

2. Press the start key. The value is set.

3. Turn the main power switch off and on. Allow more than 5 seconds between Off and On.

Completion

Press the stop key. The screen for selecting a maintenance item No. is displayed.

Summary of Contents for P-4030 MFP

Page 7: ...This page is intentionally left blank ...

Page 13: ...This page is intentionally left blank ...

Page 19: ...2NM 2NX 2NY 2NZ 2P0 2P6 5 Installation Guide PF 320 Paper Feeder ...

Page 55: ...2NM 2NX 2NY 2NZ 2P0 2P6 1 2 24 This page is intentionally left blank ...

Page 386: ...2NM 2NX 2NY 2NZ 2P0 2P6 1 5 100 This page is intentionally left blank ...

Page 486: ...Installation Guide PF 320 Paper Feeder Installation Guide ...

Page 487: ...PF 320 㾌㙼 㾌㙼 PF 320 PF 320 PF 320 㪧㪝㪄㪊㪉㪇 㪧㪝㪄㪊㪉㪇䈱 㪧㪝㪄㪊㪉㪇G 㾌 㾌 PF 320 PF 320 ...