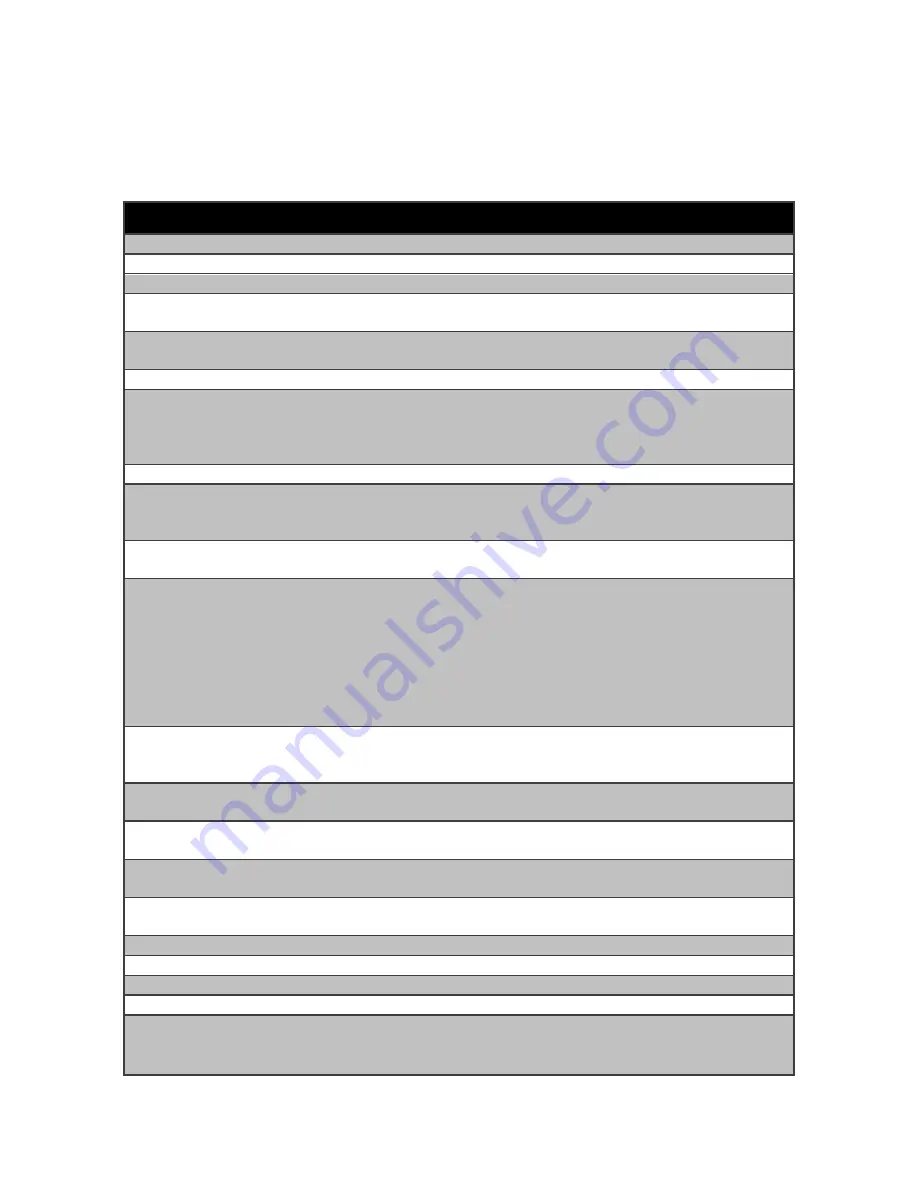

ICOLOR 900 Specifications

ICOLOR 900: System Specifications

Print Speed

Up to 9.14 meters/min (30 ft/min)

Technology

Single Pass 4 Color LED (CMYK)

Printer Processor

1

800/133 MHz

Media Width

2

Minimum: 3.0 inches ( 76.2 mm)

Maximum: 12.9 inches (327.7 mm)

Print Width

Minimum: 3.0 inches (76.2 mm)

Maximum: 12.6 inches (320 mm)

Print Length

Up to 420 meters (1378 ft)

Substrate Types

3

Die Cut Label Stock

Kiss Cut Label Stock

Non Die Cut Label Stock

Tag Stock

Print Quality

1200 x 600 dpi

Toner Supplies

4

CMY - 16,500 pages @ 5%

K - 18,500 pages @ 5%

(Rated according to ISO/IEC 19798 guidelines)

Drum Supplies

5

CMYK - 42,000 pages @ 5%

(Rated according to ISO/IEC 19798 guidelines)

Feeder System

Input roll maximum outside diameter: 12 inches (305 mm)

Core inside diameter: 3 inches (76.2 mm)

Maximum input roll weight: 60 lbs (27.2 kg)

Cut on the fly, auto cut

Auto page width registration

Front Panel LCD interface

Web management system torque

Auto adjusting form synchronization

Rewinder System

Output roll maximum diameter: 12 inches (305 mm)

Core inside diameter: 3 inches (76.2 mm)

Maximum output roll weight: 60 lbs (27.2 kg)

Dimensions (H X W X D)

Printer & Feeder: 46.3" x 25.7"x24.9" (1177 mm x 654 mm x 633 mm)

Rewinder: 16.4" x 19.7" x 21" (415 mm x 500 mm x 533 mm)

Weight

Printer & Feeder: 337.8 lbs (153.2 kg)

Rewinder: 30 lbs (13.6 kg)

Operating Environment

Temperature: 10°C to 20°C (50 to 89.6°F)

Humidity: 20 to 60% RH

Power

110 - 127 VAC, 50/60 Hz @ 880W

220 - 240 VAC, 50/60 Hz @ 440W

Certifications

FCC Class A, CE, cTUVus, CCC

Warranty

1 year – Parts & Labour

Hard Disk

40 GB internal disk

Memory

512 MB, optional 1GB

1.

Published performance results based on laboratory testing. Individual results may vary.

2.

Must use Narrow Fuser.

3.

This product is designed and engineered to operate only with genuine Uninet consumables and certified media substrates. Please

contact Uninet for the most current Certified Media List of substrates available.

54

Summary of Contents for iCOLOR 900

Page 1: ...iCOLOR 900 APEX2Print Installation and User Guide ...

Page 23: ...Navigate to the 2 Install RIP vR2 Folder Run the Prepare_Uninet_RIP_v2 1 exe file 23 ...

Page 24: ...STEP 3 of 8 The KEYLOK and Sentinel Drivers will install 24 ...

Page 26: ...STEP 5 of 8 Click Done STEP 6 of 8 26 ...

Page 27: ...Navigate to the 3 Install APEX2Print folder Run the APEX2Print_Install msi file Click Next 27 ...

Page 53: ...Appendix 53 ...

Page 57: ...57 ...

Page 59: ...PAGE 3 59 ...

Page 68: ...STEP 2 of 4 The Creating a New User Media Entry window will display Click Edit STEP 3 of 4 68 ...

Page 80: ...STEP 7 of 10 The job is ready for printing Click Print Nesting 80 ...

Page 87: ...STEP 3 The Preview Screen will display the scaled object 87 ...

Page 100: ...Example 2 Guide Arms Example 3 Cutter Blade Glue Residue Glue Residue 100 ...

Page 108: ...STEP 21 Close the Guide Door and the system is ready to print 108 ...