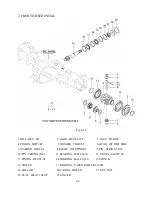

1.1 Disassembly

1) Release the bolt and nut and remove them.

2) Extract the snap ring(15) and the bearing(11) with a puller and

remove wheel gear(13)

3) Remove the brake metal tightening bolts and remove brake metal(5) with wheel pinion(7,2) and

disc brake assembly on it.

Note:

Removed oil seal(10) should be replaced

with a new one when reassembled

Fig.7-4

4) Remove the snap ring of wheel pinion(7, 2) (Fig.7-4) And individually separate the friction plates

④

,

⑤

7-4

1.2. INSPECTION

1) Friction plates.

Replace the plates whose surfaces have been

become glossy by carbonization or whose

thickness exceeds the usable limit.

Standard thickness:mm(in)

3.4 (0.133)

Usable limit:mm (in)

3.1((0.122)

Fig.7-5

Note:

Also replace those whose grooves have been worn out completely even if only on one side

4) Remove the snap ring of wheel pinion(7, 2) (Fig.7-4) And individually separate the friction plates

④

,

brake cover(5), and separator plates

⑤

from each other.

5) The cam brake can be disassembled by removing Nut.

Note:

Be careful to keep the friction surfaces of the linings, brake metals free from damage and foreign matter.

Summary of Contents for T233 HST

Page 14: ...1 11...

Page 15: ...1 12...

Page 22: ...SECTION 3 GEAR TRAIN DIAGRAMS FIG 1 3 GEAR TRAIN DIAGRAM 1 19...

Page 33: ...SECTION 2 OPERATION CHART FOR DISASSEMBLY AND REASSEMBLY BY MAJOR BLOCKS 2 4...

Page 60: ...3 HST main pump case 4 5...

Page 64: ...6 Hydrostatic system schematic 4 8...

Page 100: ...3 Rear transmission case 5 15 Fig 5 23...

Page 121: ...Power Train Diagram Fig 5 60 5 36...

Page 210: ...SECTION 6 WIRING DIAGRAM 10 12...