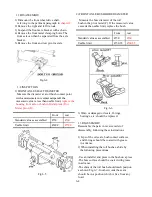

2.1 DISASSEMBLY

Oil seal

Snap ring

Snap ring

Diff case

1) As concerns operation prior to removal of

the front axle,refer to the paragraph covering

disassembly of the center pivot

2) Remove both wheels

3) Remove the drain plug from the final case and

drain oil from the final case.

4) remove both final case assembly (A and B)

from the front axle( Fig.6-11)

6) Remove the bearings from the Axle housing

And the ring gear, and then the ring gear can

be separated from the Axle housing.

7) Remove the straight pin(4) which retains the

axle housing.

Note: Discard the removed straight pin and oil

seal and install a new pin and Oil seal

when reassembled,because this pin and oil

seal is apt to be damaged when removed.

8) Remove the snap ring and the bevel pinion

can then be removed together with the

TRB’s (Fig.6-11)

9) When separating the TRB’s from the bevel

pinion,release the calking of the lock nut and

remove the bearings.

Lock Nut

Oil seal

Bevel pinion

Fig.6-11

5) Remove the oil seal, assuring parallelism of

the ring gear and bearing

Note:

The number of shims(1) installed and the the

shimming thickness should be noted for later

reference.

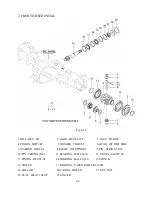

Fig.6-12

Fig.6-13

Note:

The lock nut should be calked at a point

completely apart from the threads may damage

the threads of the bevel pinion.

2.2 INSPECTION

1) visually check the bearing surfaces of the

bevel pinion and ring gear teeth.

Note:

The bevel pinion and the ring gear should be

replaced as a pair.

2) seriously worn or damaged parts should be

replaced.

6-7

Summary of Contents for T233 HST

Page 14: ...1 11...

Page 15: ...1 12...

Page 22: ...SECTION 3 GEAR TRAIN DIAGRAMS FIG 1 3 GEAR TRAIN DIAGRAM 1 19...

Page 33: ...SECTION 2 OPERATION CHART FOR DISASSEMBLY AND REASSEMBLY BY MAJOR BLOCKS 2 4...

Page 60: ...3 HST main pump case 4 5...

Page 64: ...6 Hydrostatic system schematic 4 8...

Page 100: ...3 Rear transmission case 5 15 Fig 5 23...

Page 121: ...Power Train Diagram Fig 5 60 5 36...

Page 210: ...SECTION 6 WIRING DIAGRAM 10 12...