A01715

(2)

(1)

(5)

(4)

(3)

CO07A--01

CO1267

Lock Plate

Lock Plate

Core

CO0317

Normal

f

X

X Twisted

Twisted

O--Ring

A01603

Tap

CORRECT

Tank

WRONG

Look

Plate

--

COOLING

RADIATOR

CO--15

RE AS S E M BLY

1. 1RZ -- E:

INSTALL OIL COOLER TO LOWE R TANK

(a)

Clean the O--ring contact surface of the lower tank and oil

cooler.

(b)

Install new O--rings (1) to the oil cooler (2).

(c)

Install the oil cooler with the O--rings to the lower tank (3).

(d)

Install the plate washers (4)

Torque:8.3 N

∙

m (85 kgf

∙

cm, 74 in.

∙

lbf

)

(e)

Install the pipes (5).

Torque:22 N

∙

m (220 kgf

∙

cm,

16

ft

∙

lbf

)

HINT:

Face the pipes in the same direction as before disassembly.

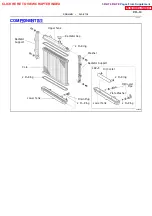

2. INSPECT LOCK PLATE

Inspect the lock plate for damage.

HINT:

S

If the sides of the lock plate groove are deformed, reas-

sembly of the tank will be impossible.

S

Therefore, first correct any deformation with pliers or simi-

lar object. Water leakage will result if the bottom of the

lock plate groove is damaged or dented. Therefore, repair

or replace if necessary.

NOTICE:

The radiator can only be recaulked 2 times.

After the 2nd time, the radiator core must be replaced.

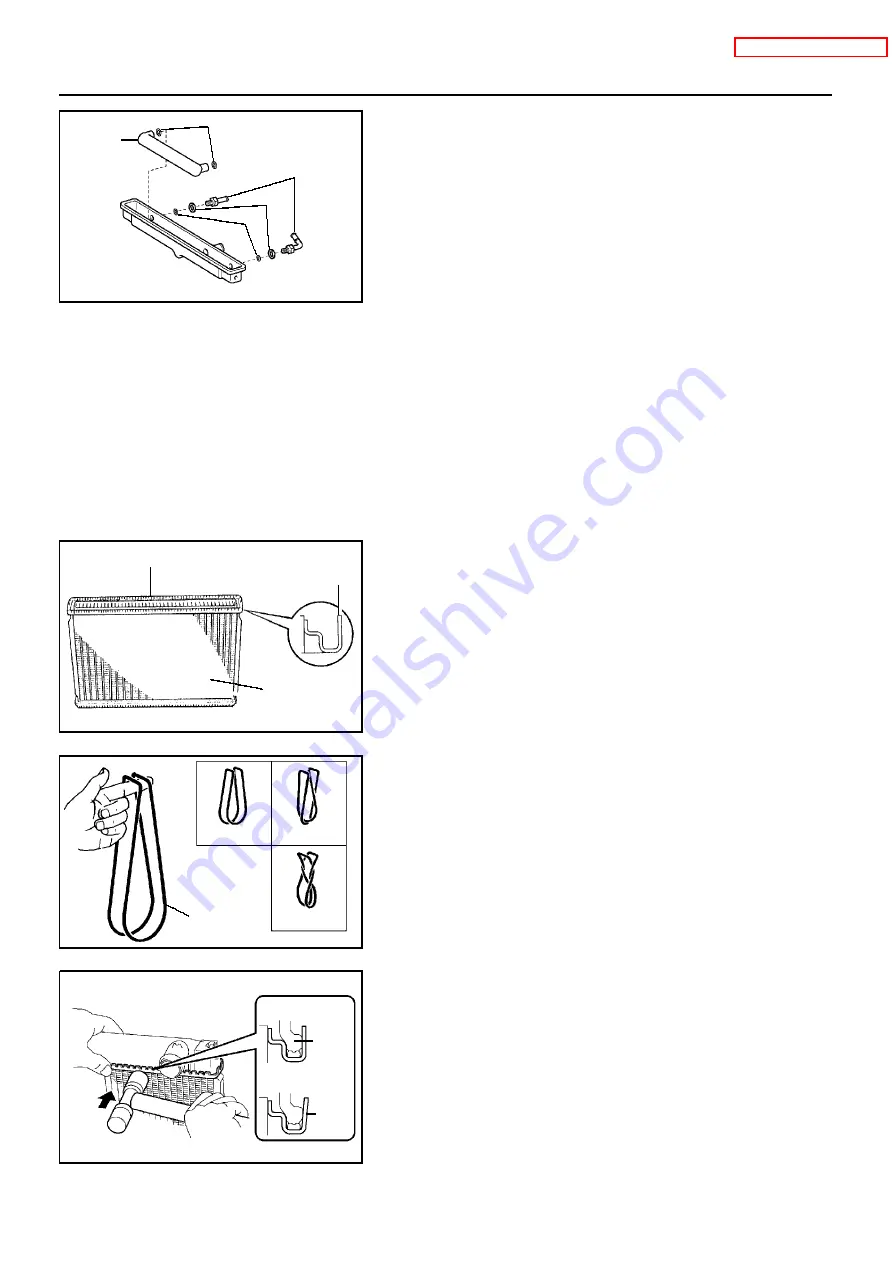

3 . I NS TALL NE W O -- RI NG S AND TANKS

(a)

After checking that there are no foreign objects in the lock

plate groove, install the new O--ring without twisting it.

HINT:

When cleaning the lock plate groove, lightly rub it with sand pa-

per without scratching it.

(b)

Install the tank without damaging the O--ring.

(c)

Tap the lock plate with a soft--faced hammer so that there

is no gap between it and the tank.

CLICK HERE TO VIEW CHAPTER INDEX

Pages From Supplement

3RZ-F,3RZ-FE