1

2

1

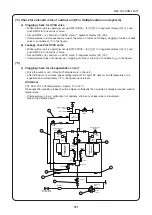

(*3) Check for solenoid valve of outdoor unit (For multiple outdoor unit system)

a) Clogging check for SV3A valve

• While outdoor unit is operating, set up SW01/02/03 = [2] [1] [3] to 7-segment display [Hr] [ 2], and

push SW04 for 2 seconds or more.

• Set up SW02 = [4], and turn on SV3A valve. (7-segment display [Hr] [ 3A])

• If temperature is low at secondary side of the valve or it does not change, clogging of valve or check

valve is considered. (

Q

in the figure.)

b) Leakage check for SV3C valve

• While outdoor unit is operating, set up SW01/02/03 = [2] [1] [3] to 7-segment display [Hr] [ 2], and

push SW04 for 2 seconds or more.

• Set up SW02 = [6], and turn on SV3C valve. (7-segment display [Hr] [ 3C])

• If temperature does not change (up), clogging of valve or strainer is considered. (

R

in the figure.)

(*4)

a) Clogging check for oil-equalization circuit

• Drive the outdoor unit. (Drive both compressors in the unit.)

• After driving for 10 minutes, check temperature of TK1 and TK2 sensors and temperature of oil-

equalization circuit capillary (

W

in the figure) were raised.

(Criterion)

TK1, TK2=Td1, Td2 temperature – Approx. 10 to 30°C

Oil-equalization capillary tubes should be higher sufficiently than outside air temperature and suction

temperature.

• If temperature is low, a malfunction of capillary, strainer, or check valve is considered.

Repair the defective parts.

(SV2)

Solenoid valve

(SV41)

(SV3D)

Check joint

High-pressure

sensor

High-pressure

SW

Oil

separator

Compressor 1

(In

v

er

ter)

Strainer

Strainer

Sensor

(TK3)

(TK1)

(SV3E)

(TK4)

(TK2)

Solenoid valve

(SV42)

High-pressure

SW

Compressor 2

(In

v

er

ter)

Sensor

(TD2)

(TD1)

Oil tank

(SV3A)

Solenoid

valve

(SV3B)

Check

valve

Strainer

5

6

4

7

3

1

7

2

Balance pipe

Packed valve

FILE NO. SVM-1

40

77