6 TROUBLESHOOTING FOR NETWORK CONNECTIONS

100 Locating the Equipment in the Network

Locating the Equipment in the Network

Cannot locate the equipment in the network

Problem Description

I cannot locate the equipment in the network.

Corrective Action

Improper settings may cause problems in locating the equipment in the network. Try the checklist below to detect the

cause of the problem. If the problem remains unsolved, contact your service representative.

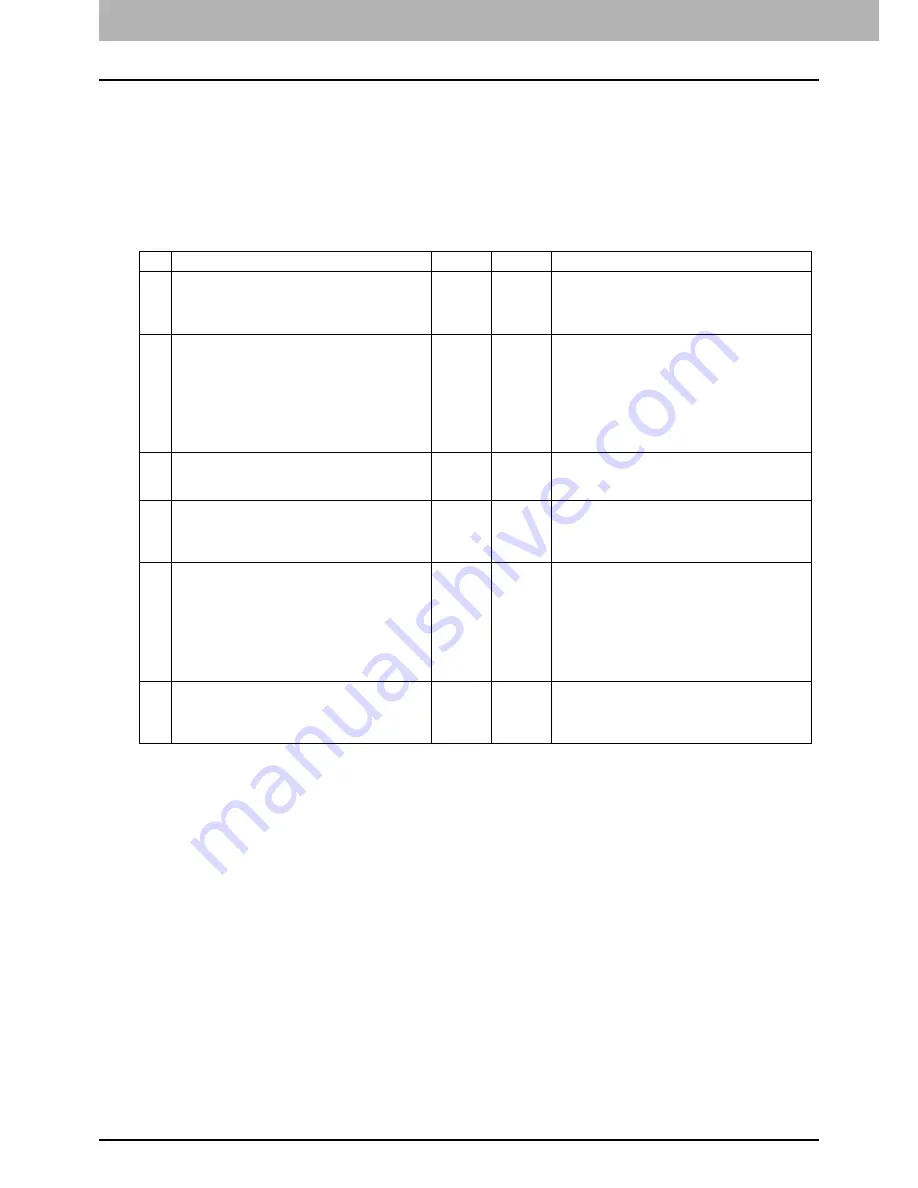

No.

Check...

Yes

No

Corrective Action

1

Is the startup page printed out? If not, wait until

the communication comes online. Examine the

protocol settings listed on the startup page. Are

they correct?

Next Step

Set up the proper protocols.

2

Print out a configuration page. Make sure that

there are not any discrepancies or inconsistencies

between the current network settings and your

network environment. Change the network

settings, if necessary. Use the Find Computer

utility from your Windows computer to locate the

equipment by its device name. Can you find the

equipment?

Next Step

Set up the proper protocol if required.

Once you have located the equipment, configure

the port that it is mapped correctly to the device.

3

Can you locate other computers connected to the

same network?

Next Step

Check the network settings on the client computer

to make sure that they are compatible with the

network settings on the equipment.

4

Check the link LED activity on the hub and/or NIC

of the equipment and the client machine. Do the

hardware components appear to be functioning

properly?

Next Step

Contact your service representative.

5

Make sure that the device name for the

equipment is unique and verify that the WINS

and/or DNS server database are not causing

potential naming conflicts with the network

settings on the equipment. If necessary, change

the network settings on the equipment. After the

communication comes back online, can you see

the equipment in the network?

Next Step

Set up the NetBIOS name of the device correctly.

6

If the network environment is using complex

subnet or supernet structures, is the IP address

used by the equipment within the network

structures range of valid addresses?

End

Contact your local network support specialist for

further assistance.

Summary of Contents for e-STUDIO

Page 1: ...MULTIFUNCTIONAL DIGITAL SYSTEMS Troubleshooting Guide ...

Page 8: ...6 CONTENTS ...

Page 10: ...Removal and Installation of the Exit Support Tray 80 ...

Page 64: ...1 TROUBLESHOOTING FOR THE HARDWARE 62 Replacing a Toner Cartridge For e STUDIO306LP ...

Page 86: ......

Page 133: ...DP 2095 2530 3020 3590 4590 5010 DP 3030 OME110056E0 ...