Greensmaster 3300/3400

Page 6 -- 37

Electrical System

Parking Brake Switch

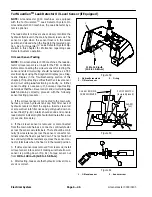

The parking brake switch is a normally open proximity

switch that mounts to the frame bracket used to attach

the parking brake lever assembly (Fig. 43). The sensing

plate for the brake switch is a tab on the parking brake

lever assembly. The Toro Electronic Controller (TEC)

monitors the operation of the parking brake switch.

When the parking brake is not applied, the tab on the

parking brake lever is positioned near the target end of

the parking brake switch so the switch is closed. The tab

on the parking brake lever is moved away from the

switch when the parking brake is applied causing the

switch to open.

Testing

1. Park machine on level surface, lower cutting units,

stop engine and remove key from ignition switch.

2. Before disconnecting the parking brake switch for

testing, the switch and its circuit wiring should be tested

as a TEC electrical input using the Diagnostic Display

(see Diagnostic Display in the Troubleshooting section

of this chapter). If input testing verifies that the brake

switch and circuit wiring

are

functioning correctly, no fur-

ther brake switch testing is necessary. If, however, input

testing determines that the brake switch and circuit wir-

ing

are not

functioning correctly, proceed with the fol-

lowing parking brake switch testing procedure.

3. Locate parking brake switch. Make sure that parking

brake is not applied.

4. Turn ignition switch to the RUN position (do not start

engine) and check LED on cable end of parking brake

switch. The switch LED

should be

illuminated when the

parking brake

is not

applied.

5. With the ignition switch still in the RUN position (do

not start engine), apply parking brake and check LED on

cable end of parking brake switch. The switch LED

should not be

illuminated when the parking brake

is

applied.

6. If the brake switch LED did not function correctly:

A. Make sure that parking brake switch is properly

adjusted (see Parking Brake Switch in the Adjust-

ments section of this chapter). If necessary, adjust

switch and return to step 4 above.

B. Make sure ignition switch is OFF and disconnect

the parking brake switch connector from the ma-

chine wire harness.

C. Using a multimeter, verify that the machine wire

harness connector terminal for black wire is closed

(continuity) to ground.

D. Turn ignition switch to the RUN position (do not

start engine) and verify with a multimeter that ma-

chine wire harness connector terminal for pink wire

has system voltage (12 VDC) present.

E. If black wire is closed to ground, pink wire has

system voltage present and switch LED did not func-

tion, replace parking brake switch. Adjust switch af-

ter installation (see Parking Brake Switch in the

Adjustments section of this chapter).

7. After brake switch testing is complete, make sure

that switch connector is plugged into machine wire har-

ness.

1. Brake lever

2. Parking brake switch

3. Switch LED location

4. Brake lever tab

Figure 43

2

1

3

4

1. Parking brake switch

2. Parking brake lever

3. Jam nut (2 used)

4. Lock washer (2 used)

Figure 44

2

1

3

4

3

4

162 to 198 in--lb

(18.4 to 22.3 N--m)

Electrical System

Summary of Contents for 04510 Greensmaster 3300 TriFlex

Page 2: ...Greensmaster 3300 3400 This page is intentionally blank ...

Page 4: ...Greensmaster 3300 3400 This page is intentionally blank ...

Page 6: ...Greensmaster 3300 3400 This page is intentionally blank ...

Page 24: ...Greensmaster 3300 Page 3 6 Gasoline Engine This page is intentionally blank ...

Page 38: ...Greensmaster 3400 Page 4 4 Diesel Engine This page is intentionally blank ...

Page 54: ...Greensmaster 3300 3400 Hydraulic System Page 5 2 This page is intentionally blank ...

Page 170: ...Greensmaster 3300 3400 Hydraulic System Page 5 118 This page is intentionally blank ...

Page 172: ...Greensmaster 3300 3400 Page 6 2 Electrical System This page is intentionally blank ...

Page 230: ...Greensmaster 3300 3400 Page 6 60 Electrical System This page is intentionally blank ...

Page 303: ...Greensmaster 3300 3400 Groomer Page 9 13 This page is intentionally blank Groomer ...

Page 318: ...Greensmaster 3300 3400 Page 10 2 Foldout Drawings This page is intentionally blank ...

Page 332: ...Page 10 16 This page is intentionally blank ...