Model: TTT-710

9.3 Other Troubles and Countermeasures

- 105 -

(Continued from previous page)

Trouble contents

Cause

Countermeasure

Error message is not

displayed even though

the waste solution tank

is full

•

Liquid level sensor alarm setting is

invalid.

•

Validate the liquid level sensor alarm setting.

>>

(4) “Liquid level sensor alarm setting” in

6.2 “Various Conditions Setting”

•

Waste solution tank liquid level

sensor is faulty.

•

Replace the liquid level sensor.

>>

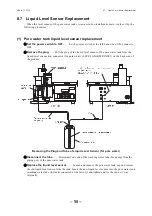

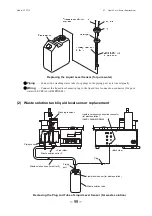

(2) “Waste

solution tank liquid level sensor replacement” in

8.7 “Liquid Level Sensor Replacement”

“RINSE2 EMPTY

Checked RINSE2

Tank” error message is

displayed even through

the liquid level in the

reagent tank is

sufficient.

•

Reagent tank liquid level sensor is

not connected to the external signal

box.

•

Replace the liquid level sensor.

>>

(4)

“Reagent washing kit connection” in 4.6

“Optional Parts Connection”

•

Reagent tank liquid level sensor is

faulty.

•

Replace the liquid level sensor.

•

External signal box is not connected

to the product main body.

•

Connect the external signal box.

>>

(4)

“Reagent washing kit connection” in 4.6

“Optional Parts Connection”

An error message is

not displayed even

through the liquid level

in the reagent tank is

insufficient.

•

Liquid level sensor alarm setting is

invalid.

•

Validate the liquid level sensor alarm setting.

>>

(4) “Liquid level sensor alarm setting” in

6.2 “Various Conditions Setting”

•

Washing water tank liquid level

sensor is faulty.

•

Replace the liquid level sensor.

Measurement does not

start even through the

analytical instrument

start key was pressed.

•

Communication cable with

analytical instrument is not

connected.

•

Connect the communication cable.

>>

(2)

“Connection to analytical instruments” in 4.2

“Wiring”

•

The display of this product is not

“READY” display.

•

Make the display of this product “READY”

(Measurement Waiting screen).

Continuous

measurement is not

ended by the specimen

in which end detection

pin is inserted.

•

End table No. setting is lower than

the table No. with inserted end

detection pin.

•

Set the set value of end table No. to the maximum

number of table specimens or to “0” (endless).

>>

(2) “Measurement conditions setting” in 6.2

“Various Conditions Setting”

•

Magnetic force of end detection pin

has dropped.

•

Replace the end detection pin.

•

Reed switch inside the product is

faulty.

•

Contact DKK-TOA or your sales representative.

Continuous

measurement is not

ended by specimen of

the set end table No.

•

End detection pin is inserted at

number lower than the set end table

No.

•

Pull the end detection pin and fix it to the end

detection pin holder.

An abnormal sound

like application of a

load is generated at

electrode arm up/down

operation.

•

Grease coating of the elevator shaft

has been consumed.

•

Contact DKK-TOA or your sales representative.

•

Foreign matter has accumulated at

elevator shaft.

Electrode and titration

nozzle touch the

measurement beaker

when the electrode arm

moves down.

•

Electrode cartridge is not suitable

for the size of the table plate

beaker.

•

Select an electrode cartridge suitable for the

beaker size.

•

Center of electrode arm has

deviated from the center of the

beaker.

•

Adjust the electrode arm position.

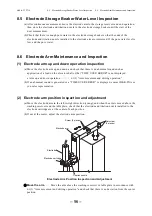

>>

(2)

“Electrode arm position inspection and

adjustment” in 8.6 “Electrode Arm Maintenance

and Inspection”

Electrode and nozzle

touch the washing

reservoir and storage

beaker when the

electrode arm moves

down.

•

Center of electrode arm has

deviated from the center of the

washing reservoir and storage

beaker.

•

Adjust the electrode arm position.

>>

(2)

“Electrode arm position inspection and

adjustment” in 8.6 “Electrode Arm Maintenance

and Inspection”

(To be continued)

Summary of Contents for TTT-710

Page 115: ... 114 ...

Page 117: ... 116 ...