9

2 February, 2005 Code Sheet V4.01d (NZ1001)

FOR VOLTAGE

0 No function

1 Peak detector

2 Pressure with Auto-cal

FOR THERMOCOUPLE

0 Type J

1 Type K

2 Type R

3 Type S

4 Type T

5 Type B

6 Type N

7 For sensor tables other than those listed above

contact Texmate

FOR RTD TYPE (2-, 3-, 4- WIRE)

0 Resistance

1 Pt 385 100

Ω

RTD

2 Pt 392 100

Ω

RTD

3 Ni 120

Ω

RTD

4 Cu 10

Ω

RTD

FREQUENCY RANGE SELECTION

0 99.999 Hz range from 0.010 Hz

1 99.999 Hz range from 2.000 Hz

2 999.99 Hz range from 0.01 Hz

3 999.99 Hz range from 2.00 Hz

4 9999.9 Hz range from 0.1 Hz

5 9999.9 Hz range from 2.0 Hz

6 99 kHz range from 1 Hz (1 s gate)

7 655.35 kHz range from 10 Hz (0.1 s gate)

PERIOD MEASUREMENT SELECTION

0 99.999 s

1 9.9999 s

2 999.99 ms

3 99.999 ms

COUNTER/RESIDENT TIMER/CLOCK SELECTION

0 Counter input with 16-bit Pre-scaler

1 Setting of 16-bit Pre-scaler

2 Debounced Counter with Pre-scaler

3 Up/Down Counter with Pre-scaler

4 0.1 sec Timer with Pre-scaler

5 –

6 External 24-hour clock

7 Internal 24-hour clock

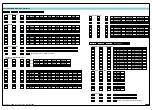

NOISE REJECTION, ANALOG SAMPLING AND OUTPUT RATE

MEASUREMENT TASK

0 Voltage, Current

1 TC (3rd digit selects type of TC)

2 RTD/Resistance 3-wire (3rd digit selects type of RTD)

3 RTD/Resistance 2- or 4-wire (3rd digit selects type of RTD)

4 Frequency

5 Period

6 Counter

7 Smart Input Module

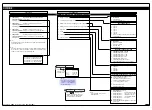

CODE 2 – CHANNEL 1 MEASUREMENT TASK AND SAMPLING RATE

SMART INPUT MODULE

0 Output Register 1

1 Output Register 2

2 Output Register 3

3 Output Register 4

4 Output Register 5

5 Output Register 6

6 Output Register 7

7 Smart Input Module

Register 1

Code Setup.

See Note 6.

THIRD DIGIT

FIRST DIGIT

SECOND DIGIT

CODE 2

Note 6:

Only available with selected

input modules.

1 =

0.1 second

10 =

1 second

600 =

1 minute

3600 =

1 Hour***

X61 Selects Prescaler

Note:

The register map is dif-

ferent for each smart

input module. See spe-

cific smart input module

data sheet.

***Note:

For the 1 hour setting, the

scale factor for CH1 must be

set to 0.1 in the calibration

mode setting [111].

Use

buttons to set

prescale values

Use the

buttons to set the

required smart input module code

(0 to 377). See specific input mod-

ule data sheet for code details.

0 Sample Rate:

Typically 10 samples/second at 60 Hz

Control Output Rate: 0.1 seconds

See Example

1

Sample Rate

:

Typically 10 samples/second at 50 Hz

Control Output Rate

: 0.1 seconds

See Example

2

Sample Rate

:

Typically 10 samples/second at 60 Hz

Control Output Rate

: Counter or 10 millisecs Control Output Rate

See Example

3

Sample Rate

:

Typically 10 samples/second at 50 Hz

Control Output Rate

: Counter or 10 millisecs Control Output Rate

See Example

Note:

Output Rate refers to setpoint and macro outputs, and input rates from

smart input modules.

Note:

All above sample rates are quoted for single channel operation. Where

more than one channel is available, sample rates are divided by the

number of active channels. See Example below.

1 Channel

= 10 samples/second

2 Channels = 5 samples/second

3 Channels = 3.33 samples/second

4 Channels = 2.5 samples/second

Example: 10 Samples/Second