20

2 February, 2005 Code Sheet V4.01d (NZ1001)

3

38

80

0 S

Se

erriie

es

s

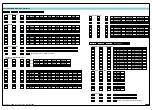

Commonly Used Registers

Data

Source

for

Analog

Outputs

1 to 7

Data

Source

for

Setpoints

Reset

Dest.

Reset

Source

Data

Source

for

Totalizers

1 to 6

Register Functions

Register

Numbers

Data

Source

for

Displays

Data

Source

for

Peak &

Valley

Display [DiSP]

1

●

●

●

●

Result [RESULT]

7

●

●

●

●

●

●

●

CH1 [CH_1]

9

●

●

●

●

●

●

●

CH2 [CH_2]

11

●

●

●

●

●

●

●

CH3 [CH_3]

13

●

●

●

●

●

●

●

CH4 [CH_4]

15

●

●

●

●

●

●

●

CH5 [CH_5]

17

●

●

●

●

●

●

●

CH6 [CH_6]

19

●

●

●

●

●

●

●

CH7 [CH_7]

21

●

●

●

●

●

●

●

Total 1 [TOT_1]

37

●

●

●

●

●

●

Total 2 [TOT_2]

39

●

●

●

●

●

●

Total 3 [TOT_3]

41

●

●

●

●

●

●

Total 4 [TOT_4]

43

●

●

●

●

●

●

Total 5 [TOT_5]

45

●

●

●

●

●

●

Total 6 [TOT_6]

47

●

●

●

●

●

●

Peak 1 [PEAK_1]

57

●

●

Valley 1 [VALEY_1]

59

●

●

Peak 2 [PEAK_2]

61

●

●

Valley 2 [VALEY_2]

63

●

●

Peak 3 [PEAK_3]

65

●

●

Valley 3 [VALEY_3]

67

●

●

Tare [TARE]

77

●

Auxiliary 1 [AUX_1]

79

●

Auxiliary 2 [AUX_2]

81

●

Auxiliary 3 [AUX_3]

83

●

Auxiliary 4 [AUX_4]

85

●

Auxiliary 5 [AUX_5]

87

●

Auxiliary 6 [AUX_6]

89

●

Auxiliary 7 [AUX_7]

91

●

Auxiliary 8 [AUX_8]

93

●

Auxiliary 9 [AUX_9]

95

●

Auxiliary 10 [AUX_10]

97

●

Auxiliary 11 [AUX_11]

99

●

Auxiliary 12 [AUX_12] 101

●

Auxiliary 13 [AUX_13] 103

●

Auxiliary 14 [AUX_14] 105

●

Auxiliary 15 [AUX_15] 107

●

Auxiliary 16 [AUX_16] 109

●

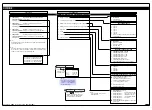

A Tiger 380 Series controller has 65536 registers avail-

able for use by the meter’s operating system and the

Tiger Macro Development System (TDS).

See TDS Macro Tutorial (NZ212) for further information

on developing macros for Tiger 380 Series controllers.

38 Manually Selectable Registers

Using the front panel buttons, there are 38 named regis-

ters that may be selected for use within the following

functions:

• [

CODE_1] - Display Configuration [X50]

. Selection

of a register as the data source for displays and peak

and valley.

•

Setpoint Control Settings [X1X]

. Selection of a reg-

ister as the data source for a setpoint.

•

Setpoint Control Settings [XX7]

. Selection of a des-

tination register that is reset by a setpoint with the

contents of a selected source register.

•

Setpoint Control Settings [XX7]

. Select the contents

of one register to be copied into another register by a

setpoint.

The 38 named registers that can be selected as a data

source, a reset source, or a reset destination for the

above functions are shown in the table opposite.

The table shows, in seven columns, the functions where

these registers can be used.

Where a register is more likely to be used in a particular

function, a closed circle

●

is shown in the column. For

those functions where a register is less likely to be used,

an open circle

is shown.

Beginning at [OFF] on the display, when selecting a reg-

ister as the data source, reset, or destination for a func-

tion, pressing the

button takes you through the named

registers to the numerical register list beginning at regis-

ter [111] and proceeding to register [16383].

Pressing the

button takes you back to [OFF].

Registers that Should Not be Used

A number of the available numerical list registers are reserved for

future use or used by the controller’s operating system and are too

numerous to list here. A list of the registers used by Tiger 380 Series

controllers is available on request from Texmate.

When selecting a data source for any of the functions requiring a

data source, only select known numerical register as your data

source.

CAUTION:

Selection of an unknown register may cause a

malfunction.

Use the

and buttons

to cycle thru the Registers

Menu and Registers (111 to

16383) to select the data

source for displays, peak and

valley, totalizers and analog

output.

[TARE]

[RESULT]

[DISP]

The button

takes you forward.

[VALY_1]

[PEAK_1]

[AUX_1]

to

[AUX_16]

Constant pressure on the

button moves thru Registers

111 to 16383 one register at

a time.

Note, not all registers

between 111 and 16383 are

available.

Registers

[ 111]

to

[16838]

[TOT_1]

to

[TOT_6]

[CH_1]

to

[CH_7]

[VALY_2]

[PEAK_2]

[VALY_3]

[PEAK_3]

The

button

takes you back.