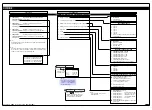

0 ON-DEMAND

Functions Activated

by Pressing the

PROGRAM Button

1 Calibration

Procedures

2 Related Calibration

Functions

3 -

0 No function

1 On Demand TARE from the

PROGRAM button

2 On Demand Single-point

Calibration from the PROGRAM

button (requires single input

source)

3 On Demand 2-point Calibration

from the PROGRAM button

(requires dual input source)

4 On Demand Primary Input

Compensation Mode from the

PROGRAM button

5 On Demand Manual Loader

Mode (no increase / decrease

with HOLD active)

6 -

7 -

Note:

When in the TARE mode, a deci-

mal point appears at the right of

the display indicating that the tare

value is NOT zero.

6

2 February, 2005 Code Sheet V4.01d (NZ1001)

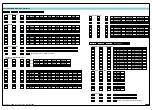

CALIBRATION MODES FOR INPUT AND OUTPUT

FIRST DIGIT

SECOND DIGIT

See Page 7 for a breakdown of

the sub-menu

Use buttons

to set SPAN

Press the PROGRAM button for 4 seconds to

tare

the selected channel

4 secs

4 secs

Use buttons

to set ZERO

Use buttons

to set SPAN

4 secs

Use

buttons to ADJUST primary input

compensation value from –199999 to 999999

Use

buttons to ADJUST the value on the selected channel

from –199999 to 999999 via the manual loader output. See Note*

4 secs

4 secs

Press the PROGRAM button for 4 seconds to

display

the single-point calibration settings

When all 3 digits are selected and the meter is running in the operational display, press

the

button for 4 seconds to

activate

the selected on-demand function

Use buttons

to set SCALE

Use

buttons to set

OFFSET

Use buttons

to set ZERO

Use buttons

to set SPAN

All smart input modules have individual calibration procedures.

See the specific smart input module data sheet for setup procedures

Use buttons

to set CAL_LO

Use buttons

to set CAL_HI

0 Manual Calibration

(requires NO input source)

1 2-point Calibration

(requires dual input source)

2 Calibrate Thermocouple

(requires K type thermocouple

input source)

3 Calibrate RTD

(requires RTD 385 input source)

4 Calibrate Smart Input Module.

Note: This function is not avail-

able on all input modules

5 Calibrate Analog Output mA/V

(Single analog out requires multi-

meter connected to pins 2 and 3

on Terminal 4)

6 -

7 -

Example

Example

0

-

1

Analog Output 1

2

Analog Output 2

3

Analog Output 3

4

Analog Output 4

5

Analog Output 5

6

Analog Output 6

7

Analog Output 7

Note, settings 3-7 not avail-

able at present

THIRD DIGIT

0

-

1

CH1

2

CH2

3

CH3

THIRD DIGIT

0

-

1

CH1

2

CH2

3

CH3

4

CH4

THIRD DIGIT

See

CH1 Thermocouple Calibration

on Page 21 for a procedure.

See

CH1 RTD Calibration

on Page 22 for a procedure.

DEFAULT 3rd Digit

OBJECT FOR 2nd DIGIT

0

Result

1

Channel 1

2

Channel 2

3

Channel 3

4

Channel 4

5

Channel 5

6

Channel 6

7

Channel 7

THIRD DIGIT

When in this setting, the destination channel

is only updated after the

button is pressed

When in this setting, the destination channel is

updated as the

or

button is pressed

Note*:

For the Manual Loader Mode (Direct Display) to work, with CAL set to [25X] the data source for the

analog output (1 or 2) must be set to [DISP].

Operating range upper and lower limits can be set for the manual loader mode. The setpoint activation

values for setpoint 5 becomes the upper limit and setpoint 6 becomes the lower limit. When either the

direct display or on demand manual loader mode is programmed into the meter, the values for setpoint

5 and setpoint 6 are activated as upper and lower limits.

See Analog Output Supplement (NZ200) for further details.