12

2 February, 2005 Code Sheet V4.01d (NZ1001)

Follow These Steps

The following procedures are written for SP1, all other setpoints are con-

figured in a similar manner.

1) Press the

and

buttons at the same time. This enters the set-

point programming mode.The display toggles between [SP_1] and

[18000].

This is SP1 of the

Setpoint Activation Values Mode

. Use the

and

buttons to set SP1 or the

button to move to the required

setpoint.

2) After all required setpoint

activation values

have been set, press

the

button until [SPC_1] appears. This is the

Setpoint & Relay

Control Settings Mode

.

SPC_1 is the

setpoint and relay control settings

programming

menu for SP1. Set the three digits according to the codes in the

Setpoint and Relay Control Function Settings

opposite in the fol-

lowing order:

Third Digit – Setpoint Delay Mode

Set to [XX5] and program the hysteresis, deviation, or PID

functions as required for SP1.

Reset back to [XX0].

Third Digit – Setpoint Timer Mode

Set to [XX6] and program the timer mode functions as

required for SP1.

Reset back to [XX0].

Third Digit – Setpoint Reset & Trigger Functions

Set to [XX7] and program the reset and trigger functions as

required for SP1.

Reset back to [XX0].

Second Digit – Setpoint Activation Source Mode

Set to [X1X] to select the setpoint activation source for SP1

from any channel or selected register shown above. Reset

back to [X0X].

If the SP source is from an external digital input, set to one of

either [X2X] to [X7X] to select the setpoint activation source

from one of six digital inputs (2 to 7).

See *Note at 2nd digit.

First Digit – Relay Energize Mode

Select the relay energize mode for SP1 from 0 to 3.

Third Digit – Relay Latching & Manual Reset Functions

Program the third digit setpoint relay latching and manual

reset functions between 0 to 4 as required.

3) Press the

button to move to move to [SPC_2].

4) Repeat Step 2 for all required setpoints.

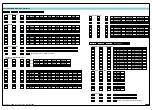

Setpoint Setup Sequence

0 No

Latching

1 Relay Latched ON

2 Manual Relay Reset

3 Relay Latched and Manual Relay

Reset

4 Relay Latched Off

5 Mode: Hysteresis, Deviation, PID,

SP Flashing, SP Tracking

6 Timer

Modes:

• OFF

• Normal Delay

• Repeat ON

• Pulse ON

• 1-Shot ON

• Repeat OFF

• Pulse OFF

• 1-Shot OFF

Note:

In PID Mode, all Timer Modes on

SP1 set in [XX6] are not functional.

7 Advanced Functions Mode:

• OFF.

• Reset Trigger.

• Reset Destination.

• Reset Mode.

• Reset Constant.

• Trigger Print from SP.

• Trigger Log from SP.

Note:

[XX5], [XX6], and [XX7] are set up

procedures only. To finish, reset to

0-4 as required for setpoint latching

and relay reset modes.

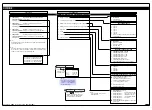

SETPOINT PROGRAMMING MODE – SPC_1 to SPC_6

Relay Energize Function

0 Relay energizes ABOVE setpoint value

1 Relay energizes BELOW setpoint value

2 Relay energizes AT OR ABOVE setpoint value with FALLING INPUT

SIGNAL INITIAL START-UP INHIBIT

3 Relay energizes BELOW setpoint value with RISING INPUT SIGNAL

INITIAL START-UP INHIBIT

See Page 15 for a detailed description of the relay energize options.

SP Activation Source

0

Activate Setpoint Source from

Selected Register

1 Select Data Source for Setpoint

Note:

[X1X] is a register selection procedure

only. To finish, reset to [X0X] to activate

the selection, or reset to 2-7 as required

for digital input selection.

2 Digital

Input

– Capture Pin

3 Digital

Input

– D1 (selected input modules)

4 Digital

Input

– D2 (selected input modules)

5 Digital

Input

– D3 (selected input modules)

6 HOLD Pin

7 LOCK Pin

*Note:

If the setpoint source is set to [oFF] or a

digital input, the setpoint activation value

will have no effect and will not be dis-

played.

SP Functions

FIRST DIGIT

SECOND DIGIT

THIRD DIGIT

SETPOINT AND RELAY CONTROL FUNCTION SETTINGS

Go to

Page 13

Go to

Page 13

Go to

Page 14

Select Source for Setpoint Functions

[TARE]

[RESULT]

[DISP]

The button

takes you forward.

[VALY_1]

[PEAK_1]

[AUX_1] to [AUX_16]

Constant pressure on the

button

moves thru Registers 111 to 16383

one register at a time.

Note, not all registers between 111

and 16383 are available.

Use the

and

buttons to cycle thru the

Registers Menu and Registers (111 to 16383)

to select the data source for displays, peak and

valley, totalizers, and analog output.

Registers [ 111] to [16383]

[TOT_1] to [TOT_6]

[CH_1] to [CH_7]

[VALY_2]

[PEAK_2]

[VALY_3]

[PEAK_3]

The

button

takes you back.