Preparing job computer sprayer for use

31

990267EN ind. A

⇨

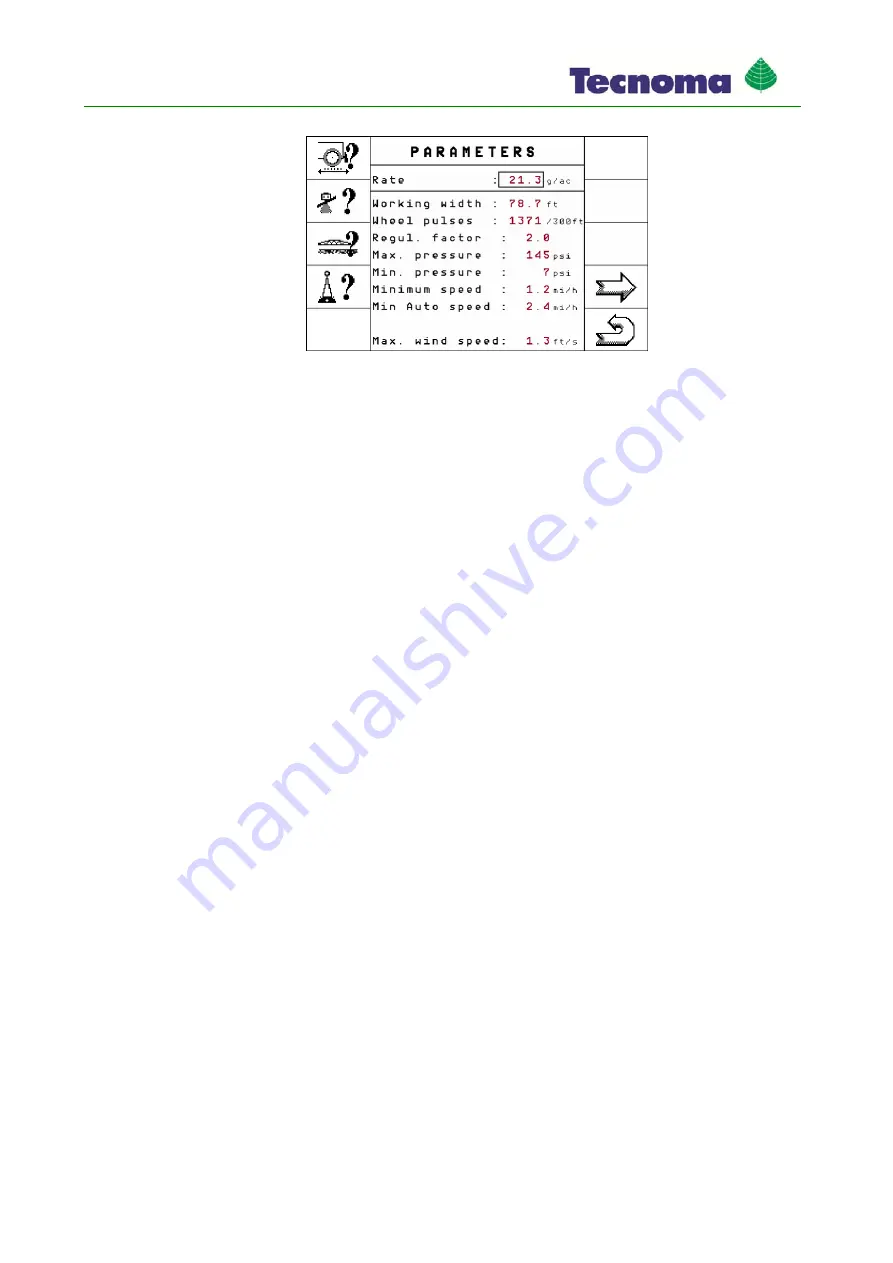

The following screen will appear:

2.

Click on the line with the desired parameter.

⇨

The data input screen appears.

3.

Input desired value.

4.

Highlight and click on "OK" to terminate the input and apply it.

⇨

The new value appears in the "Parameters" screen.

The list contains all parameters that can appear on the screen. Which parameters appear on your

screen depends on the type and configuration of your field sprayer.

Nozzle

Color of the activated nozzles.

The colors are specified by the ISO standard. They can also be calibrated. [

➙

43]

Rate

The volume entered as the rate will be applied when the field sprayer is working in automatic mode.

Working width

Field sprayer working width.

Wheel pulses

Number of pulses the wheel sensor sends to the job computer on a 100m route. Used to calculate

speed.

The number is determined by the wheel sensor calibration.

Regul. factor

In Automatic mode the spray pressure of the nozzles will be adapted to the current speed of the field

sprayer. The adaption should ensure that the volume of spray liquid that is spread is exactly what you

defined in the rate. In this the regul. factor plays a decisive role.

The regul. factor adjusts the control speed:

▪

The higher the regul. factor, the faster the spray pressure is adjusted.

▪

The lower the regul. factor, the more slowly the spray pressure is adjusted.

When setting the regul. factor, take note of the following:

List of parameters