TCF Termoventilatori Condizionatori Felsinea Srl

40057 Cadriano di Granarolo Emilia (Bologna), via Giuseppe di Vittorio 5

www.tcf.it

3

3.

ASSEMBLY ON SITE

3.1

POST-TRANSPORTATION CHECK

Upon arrival of the air-conditioning unit on site, TCF suggests

the customers to perform an accurate check of the structure

and of the components.

Should any transportation damage be detected, this must be

notified on the delivery bill. The carrier must immediately file

a report of the accident to obtain compensation from the

insurance company.

3.2

PRESERVATION ON SITE

In order to keep the air-conditioning unit in good and

efficient condition on site, the following steps must be taken

first:

-

prior to installation, position the unit and the

accessories in a place offering the best possible

protection against accidental knocks, dust and

atmospheric agents

-

carefully cover the inlets and outlets to prevent

foreign matter from entering the unit and damaging

the internal components

-

extract the prefilters from the unit and put them in a

protected place to preserve their filtrating

efficiency. This is why the superior efficiency filters

are delivered packed; they must be kept in their

packages until the unit is put into service

-

check that the hydraulic connections are protected

by the relevant caps, as they were delivered by TCF.

If they are not, plug them in order to protect them

exchangers.

3.3

POSITIONING

3.3.1

Dimensions of installation room

The air-conditioning unit installation room must be of

sufficient size to permit easy inspection, maintenance and

component

replacement.

Accordingly,

the

following

dimensions are recommended (fig. 3):

-

Heat exchanger extraction side:

min. distance Lb = (B+0,2) m

where B = machine width (m)

-

inspection side:

min. distance Li = 1.2 m

if you do not have the minimum space requirements as

specified above, the units doors can, on request, be fitted

using PVC clamps instead of hinges. In this case the minimum

distance will be Li = 0,7 m.

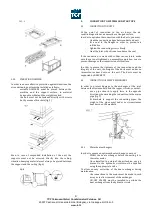

3.3.2

Base frame

The permanent installation of the air-conditioning unit may

be made:

-

directly on the floor (fig. 4a)

-

on a concrete bed (fig. 4b)

-

on a steel section bed (fig. 4c)

-

on a suspended base (fig. 4d)

Both the floor and the beds must be capable of withstanding

the machine weight to within the required safety margins.

The air-conditioning unit must be positioned on a horizontal

surface so as to prevent:

-

damage to the fan motor units caused by uneven

weights on the vibration dampers

-

malfunctioning of the condensate drains

-

difficulty in opening and closing the inspection

doors

The horizontal alignment of the support surface must be

checked with a SPIRIT LEVEL; adjustments may be made

using STEEL SHIMS.