TCF Termoventilatori Condizionatori Felsinea Srl

40057 Cadriano di Granarolo Emilia (Bologna), via Giuseppe di Vittorio 5

www.tcf.it

2

0.

INTRODUCTION

This manual has been compiled by TCF Srl to provide the

installer, customer and user with instructions intended to

ensure the proper management and use of the air-

conditioning units series T, TS, TA, PA from the delivery up to

the commissioning.

The recommendations which follow are intended to ensure a

continuous and durative operating life of the air-conditioning

unit.

The procedures described below should be performed by

skilled personnel with a good knowledge of air-conditioning

systems design and operation, even though, thanks to the

unit’s simplicity of design, these could be carried out also by

those unfamiliar with air handling.

1.

DESCRIPTION OF THE AIR-CONDITIONING UNIT

1.1

COMPOSITION

The air-conditioning unit, in single-section or multiple

sections, in its most complete execution, is made up from:

•

Return section with one or more dampers

•

Filters section

•

Heat exchanger section (heating, cooling)

•

Supply fan section

1.2

PERMITTED USE

TCF air-conditioning units are designed exclusively for CIVIL

AND INDUSTRIAL AIR TREATMENT.

In case of CORROSIVE and/or EXPLOSIVE air flows, a number

of special technical modifications must be made at the design

stage which, altogether, adapt the machine for the treatment

of special air flows.

The air-conditioning units must at all times be used strictly in

accordance with the design conditions established at the time

of contract in agreement with the customer. ANY OTHER USE

SHALL CONSTITUTE IMPROPER USE AND IS THEREFORE

DANGEROUS. THE MANUFACTURER MAY NOT BE HELD

LIABLE FOR DAMAGE CAUSED BY NON-STANDARD USE OR

ANY USE NOT ENVISAGED IN THE CONTRACT.

2.

CONTROL, PACKING, TRANSPORTATION

2.1

FACTORY INSPECTION OF THE SUPPLY

Prior to shipping, each TCF air-conditioning unit is subject to

all the functional tests listed on the attached UNIT

INSPECTION SHEET. The controls concern:

•

General machine dimensions

•

Correct assembly of the various parts and sections

•

Compliance with the various safety rules in force

•

Integrity of all the system’s component parts

•

Application of the identification, operation and

safety notices

On completion of the inspection, the Chief Inspector applies

the EC mark demonstrating product compliance with

prevailing European Union machine directives.

2.2

PACKING

The air-conditioning units are usually supplied as fully-

assembled monoblocks.

Only if the customer expressly requests it, the units can be

split into sections to facilitate transportation and carriage

through narrow apertures, stairs or corridors.

Transportation of the machines, both monoblocks and

broken-down units, may be:

-

normal

-

special

In the former case, TCF Srl does not normally pack the units.

In case of special transportation, the packing requested is

agreed at the time of contract and is entirely on the

customer’s charge.

Fragile components supplied separate from the unit, such as

humidifiers, exchangers, recuperators, filters, control boards

etc., are always delivered packed.

2.3

LOADING,TRANSPORT,UNLOADING

TCF Srl disclaims any liability for damage occurred to the air-

conditioning

unit

during

loading,

unloading

and

transportation. We therefore recommend that precautions be

taken, including:

-

The load must be firmly secured to ensure its

integrity during transportation

-

Handling must be performed without exerting force

on protruding accessories (hydraulic attachments,

handles, hinges, air locks, protection roof)

-

Do not overturn the sections as you may otherwise

break internal supports, components and dampers

-

Do not subject the unit to violent impacts as you

may damage its integrity

-

If a forklift truck is used during the loading,

unloading and handling operations, the forks of the

truck must be at least the same length as the unit to

ensure stability (fig. 1)

-

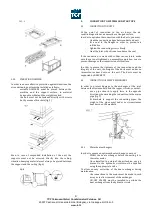

If the air-conditioning unit is fitted with a

continuous steel base frame, handling may be

carried out with a crane, using cables firmly secured

to rods (sufficient for the stress involved) passing

through the holes provided in the base.

If a crane is used, proceed as shown in the illustration,

using spacers to protect the structure (fig. 2).

-

During transportation, protect the unit from

atmospheric agents. Special care must be taken if

the unit is supplied disassembled or designed for

internal use.