TCF Termoventilatori Condizionatori Felsinea Srl

40057 Cadriano di Granarolo Emilia (Bologna), via Giuseppe di Vittorio 5

www.tcf.it

10

5.

MAINTENANCE

5.1

FOREWORD

TCF recommends that its customers carry out PREVENTIVE

MAINTENANCE on the air-conditioning units in order to

ensure a long-term efficiency.

Such air-conditioning units require little maintenance and

have been designed to make each operation as easy and safe

as possible.

5.2

FILTRATING SECTIONS

The filtrating sections require the most frequent maintenance

in order to:

-

ensure that the air is filtered with the required

efficiency in the treated environment;

-

prevent the components of the air-conditioning unit

from damaging

5.2.1

Reconditionable synthetic filters

These are cells measuring 50 or 100mm in thickness, also

known as PREFILTERS, which offer the advantage of being

reconditionable.

The RECONDITIONING may be performed using two different

methods, depending on the type of dust to be treated:

-

in case of DRY DUSTS, a compressed air jet has to be

directed against the filter in the opposite direction

to normal operation

-

in case of WET DUSTS, the filtration diaphragm has

to be washed (without removing it from the frame),

if necessary using domestic detergents. To avoid

damaging the filter, the temperature of the water

must not exceed 50°C. Do not use solvents or caustic

soda. Let the diaphragm dry by evaporation and

refit it only when it is perfectly dry.

TCF recommends TO CHECK THE CONDITION OF THE

FILTERS ON A WEEKLY BASIS.

THE PREFILTERS MUST BE RECONDITIONED EVERY 7-20

DAYS depending on the type of environment being treated.

After 7 to 10 reconditioning operations, the diaphragms will

tend to deteriorate and its original characteristics will be

impaired; it should therefore be replaced.

5.2.2

Non-reconditionable bag filters

These are filters with an efficiency between EU5 and EU9.

They CANNOT BE RECONDITIONED as this would damage

their dirt accumulation capacity and efficiency.

In order to preserve the filtration diaphragm as long as

possible, the condition of the prefilters must be carefully

monitored.

Moreover, TCF recommends to check the state of the gaskets

of the frame and the springs every week, to prevent air from

by-passing the bag without being filtered.

5.2.2.1

Replacement load loss chart

TABLE 2. Pressure drop to substitute the filters

5.3

HEAT EXCHANGERS

5.3.1

Water heat exchangers

In order to maintain an optimum water/air heat exchange,

the following MAINTENANCE OPERATIONS must be

performed regularly on the exchangers:

-

At the beginning of each operating season, remove

the air present in the heat exchanger circuit using

the relevant air relief valve;

-

At the beginning of each operating season, remove

dust and deposits from the finned pack. Proceed as

follows:

1.

use a jet of compressed air in the opposite direction

to the air flow during normal unit operation, or

2.

wash the finned pack with water, non-corrosive

components and a wire brush

-

Remove any deposit from the condensate drain pan.

This operation must be repeated every month in

order to prevent flooding of the machine and of the

room where it is installed.

To avoid causing irreparable damage to the heat exchangers,

you must make sure that the primary fluid will not freeze

when winter comes. For this purpose TCF recommends the

following steps:

-

in case of prolonged standstill of the heat exchanger

circuits, they should be completely drained

-

where an anti-freeze system based on heating

elements is provided, to protect the exchanger,

make sure that the control board is constantly

powered;

-

on systems operating with anti-freeze mixture,

check their efficiency and fill them up or replace if

necessary

ANTI-FREEZE

LIQUID

MUST

NEVER

BE

INTRODUCED INTO A CIRCUIT NOT SPECIFICALLY

SIEZED FOR THIS PURPOSE as it would jeopardize

the correct operation of the pump and the efficiency

of the heat exchanger.

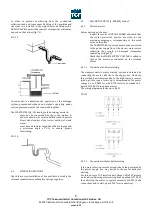

5.3.2

Extraction of the heat exchangers

Frequently insufficient space in the room makes it often

impossible to carry out the necessary maintenance on the

heat exchanger while installed inside the unit.

In these cases it is necessary to extract the exchanger, an

operation which calls for the utmost care.

To remove the exchanger you must: